Jul 10, 2025

Smarter Retrofits Start with HVAC Load Calculation

By moving away from outdated sizing methods and embracing building science principles, contractors can deliver results that truly serve the needs of the homeowner.

By: Brynn Cooksey

When designing an HVAC retrofit project, the initial step is to calculate the heat loss and heat gain loads. The load calculation represents the heating and cooling requirements necessary to maintain the comfort of a dwelling’s or building’s occupants. This calculation is critical to the entire design sequence, and if the initial part is incorrect, the equipment cannot be selected properly, the duct cannot be sized appropriately, and, ultimately, the HVAC system cannot be tested, adjusted, and balanced.

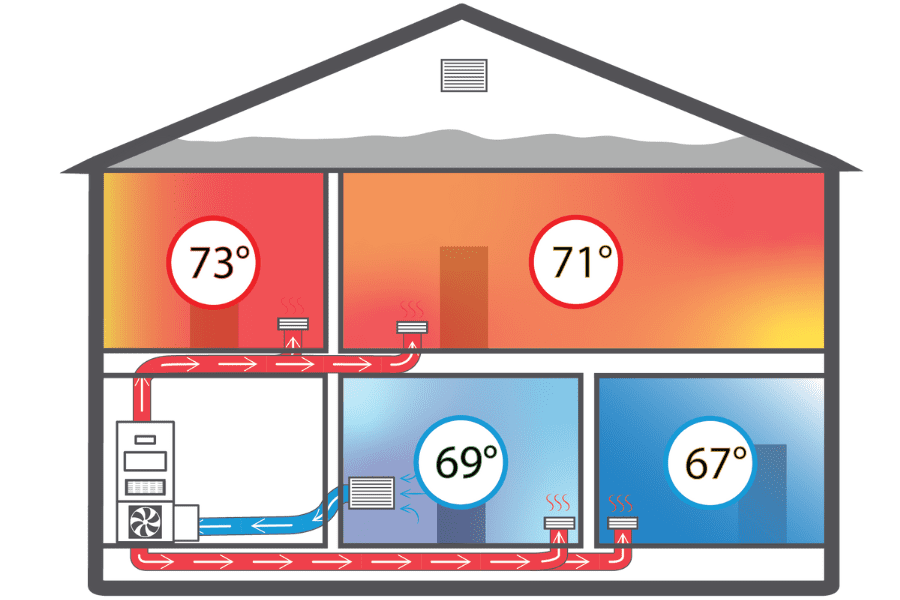

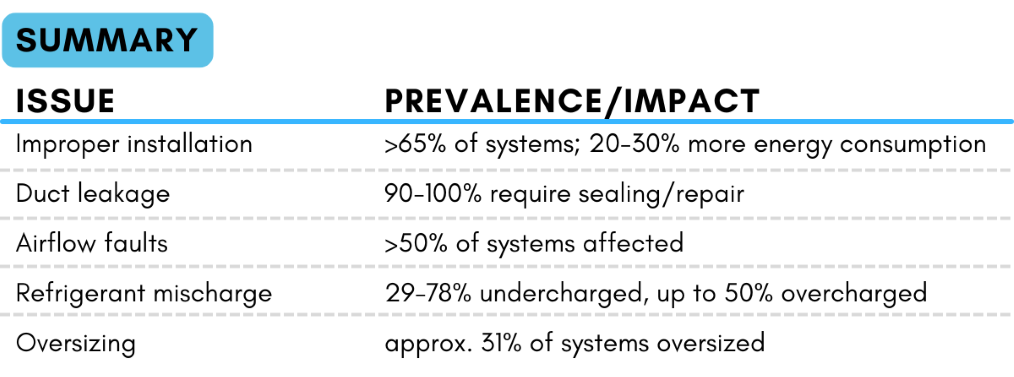

Not getting the load right leads to comfort issues, energy waste, poor equipment performance, and an increased risk of component failure due to system short cycling. One DOE report drew the following conclusions when evaluating HVAC system-related issues:

When we refer to heat gain, we mean the heat inside the building that needs to be removed, typically through the use of air conditioning. When describing heat gain sources, we calculate the load in Btu/hour that enters or is generated within the building shell. The items we need to check for include people, pets, plants, solar heat gain, heat transmission, latent heat energy, air leakage, appliances, and lighting loads. An air conditioner’s capacity is determined by the inputs of the building science professional with the assumption that the building will be utilized and operated as intended. The capacity of an air conditioner, specifically, accounts for the removal of latent (moisture) and sensible (temperature) heat.

When it comes to heat loss, the process is the same, but we consider the heat energy leaving the building’s structure. When performing a heat loss calculation, design assumptions are made for a home or building during the cold winter months, when the building is empty, none of the appliances are operating, and the sun has set. For heat loss calculations, we determine the building’s heat transmission losses to the outside and the impact of air leakage on the heating load. To offset heat loss, we use equipment such as heat pumps, furnaces, and boilers to replace the BTUs that have escaped from the building shell.

Weather data plays a crucial role in a Manual J load calculation by establishing the outdoor design conditions against which the home’s heating and cooling loads are evaluated. These conditions—typically based on 99% winter and 1% summer temperature design values—represent the most extreme temperatures a building is likely to experience during the heating and cooling seasons.

By using location-specific climate data, including temperature, humidity, and solar gain, Manual J calculations can more accurately predict the thermal load on a building. This ensures that the HVAC system is sized not for the average day but for peak demand scenarios, resulting in a design that maintains comfort even during the hottest and coldest days of the year without oversizing the equipment.

The Role of Air Conditioning Contractors Association (ACCA)

ACCA load calculations—specifically those outlined in Manual J—are the preferred method for sizing residential HVAC systems because they offer accuracy, compliance, and long-term system performance. Unlike outdated rule-of-thumb approaches, Manual J evaluates real building characteristics such as insulation levels, window performance, square footage, orientation, and infiltration rates to produce precise heating and cooling load estimates.

This level of detail helps avoid the widespread problem of oversizing, which can lead to short cycling, poor humidity control, higher utility costs, and premature equipment failure. Manual J is widely accepted by code officials and is required for programs such as ENERGY STAR and compliance with the IECC. It also integrates with Manual S for equipment selection and Manual D for duct design, ensuring the entire HVAC system is engineered correctly. Endorsed by the U.S. Department of Energy, EPA, and RESNET, ACCA’s load calculation protocol remains the gold standard for residential HVAC design.

The Building Shell’s Role in System Design

In the building science industry, we often perform whole-building retrofits, taking a whole-house approach. We perform tasks like air sealing and insulation in attics, crawlspaces, and walls to make the house more comfortable. These items will affect the calculation of heat loss or heat gain. Therefore, it is best practice to always consider the consequences before replacing HVAC equipment.

Weatherization will significantly reduce a building’s heating and cooling requirements; therefore, it is vital to have an understanding of the calculated load after weatherization. In many cases, weatherization will be necessary to ensure that the heating and cooling system operates as designed.

The Good Old Box Swapping Days and Rules of Thumb are Gone

There are two load-sizing practices you should avoid at all costs. The first is replacing a system with a like-for-like capacity without first determining if the existing equipment is correctly sized. Often, due to outdated construction practices and building codes, many systems are grossly oversized when compared to a correctly modeled load calculation. So, don’t just swap the box.

The second bad habit to avoid is sizing by a rule of thumb. Using rules of thumb to size HVAC systems—such as assigning one ton of cooling per 500 square feet—is an outdated and inaccurate practice that often leads to poor system performance. These shortcuts overlook critical factors such as insulation quality, window efficiency, air leakage, building orientation, occupant load, and regional climate.

As a result, systems are frequently oversized, leading to short cycling, inadequate humidity control, increased energy consumption, and reduced equipment lifespan. Relying on rough estimates may seem convenient, but it undermines the comfort, efficiency, and longevity of HVAC systems. Accurate load calculations, such as those performed using the ACCA Manual J, provide a data-driven approach that ensures equipment is correctly matched to the home’s actual needs.

Best Practices: Evaluating Shell Leakage with a Blower Door

Air leakage in a building has a significant impact on heating and cooling loads by allowing uncontrolled outside air to enter and conditioned air to escape. This infiltration increases the demand for HVAC systems, resulting in higher energy consumption, uneven temperatures, and reduced indoor comfort. Excessive air leakage can also compromise humidity control and exacerbate issues like drafts and condensation.

To accurately account for this variable in load calculations, blower door testing is considered best practice. By pressurizing or depressurizing a home, a blower door test measures the air changes per hour (ACH) at a specified pressure, typically 50 Pascals, providing a quantifiable value for infiltration. T

his data enables energy auditors and HVAC professionals to incorporate actual leakage rates into Manual J calculations, resulting in more precise sizing, improved system performance, and enhanced energy efficiency. ACCA Manual J does allow for estimates of shell leakage, but a blower door is far superior for accurately understanding the impacts of air leaking in the building shell.

Conclusion

In today’s high-performance home environment, proper load calculations are more important than ever. Whether you’re performing a full retrofit or simply replacing HVAC equipment, relying on Manual J and best practices like blower door testing ensures that your system performs efficiently, maintains comfort, and avoids the costly consequences of oversizing.

By moving away from outdated sizing methods and embracing building science principles, contractors can deliver results that truly serve the needs of the homeowner—and the integrity of the profession.