Aug 11, 2022

How Contractors Can Address their Workforce Challenges

Loads of federal funds are currently being allocated to workforce development.

By: Charles Cormany

We, at Efficiency First California, have been doing a lot of outreach to contractors lately. Our goal is to find out what their pain points are and determine if there is something we, as a contractor organization, can do to help.

After scores of conversations, we continue to hear the same feedback. Contractors are struggling with supply chain issues and are having difficulty finding and keeping good workers. Two years after COVID-19 hit the world, the global supply chain is slowly recovering, but the workforce issue remains.

The trades have been facing workforce challenges since for over a decade, long before COVID threw a wrench into the gears of the global economy. The Great Recession brought the entire construction industry to a standstill. Many young people realized it didn’t make sense to pursue a career that included filing for unemployment as soon as you graduate. An entire generation of potential skilled labor bypassed trade schools and pursued other careers. The dot com boom was making overnight millionaires for youth with tech-related skills, compounding the problem.

Some trade jobs are more difficult to fill than others. For some reason finding good HVAC technicians is hard. I worked at a company with a dedicated human resource specialist (HR) who had listings for HVAC technicians for the entire three-plus years I worked there. I think all told; we hired two technicians during that time. It was hard to find HVAC techs then. It’s still tough now.

The lack of skilled workers is more than an inconvenience to contractors. Most of the policies we are putting in place to meet greenhouse gas reduction goals rely on skilled labor in one form or another. Experts predict the clean energy economy will create thousands of new jobs, which is good, but where will we find workers to meet the demand? What happens as the industry grows if it’s this hard to hire good employees today? We can’t foster growth in the industry without a viable workforce.

So what can contractors do? Here are a few suggestions for easing some of the pain of trying to bring on new employees.

Make Sure Your Crew is Aligned with Your Goals

One of my failings as a contractor was to bring on new employees who did not buy into what we were trying to achieve. Improving the performance of an existing building requires paying attention to the details.

Some of these details might seem trivial to an under-educated new employee. Air sealing is a good example. Air sealing itself is not a challenging task to master. Put on some protective gear, head into the attic and crawlspace of a house, and fill all the holes you see with single-part expanding foam. It’s cheap to do, pretty easy, and if done well, effective. The problem is that the gaps you choose to fill or not fill can significantly impact the effectiveness of your efforts.

My favorite example is the giant hole under a bathtub. Plumbers routinely cut massive holes in the floor to install the drain fixtures in bathtubs. We used to seal them with rigid foam insulation and single-part gun foam. You can air seal an attic all day long and have less impact than filling a single hole under the bathtub. Educating your crews is crucial and should be factored into your business model if your goal is quality work.

Provide On-the-Job Training

Efficiency First California used to do all kinds of classroom training. When folks are out of work and looking for a new job, they will sit in classrooms for hours on end. A decade ago, we educated scores of people about the benefits and best practices of building science. We hired industry experts to travel to various parts of the state, providing classroom education to large groups.

Today, workers are in higher demand, making them much less likely to attend classroom training. There is an opportunity cost to in-person education, which is a tough sell. Why attend a class when you can be making money?

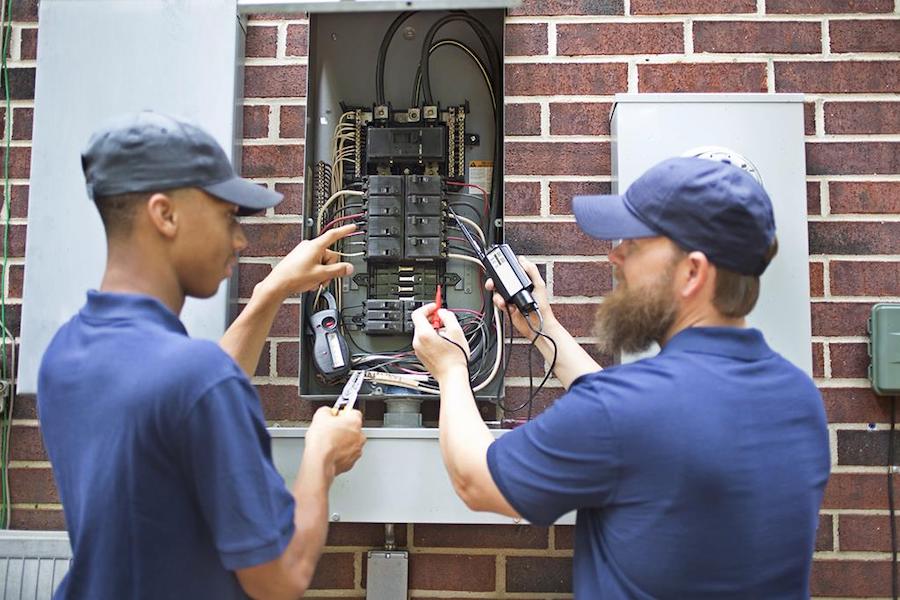

The most effective way to educate workers today is on-the-job training (OJT). It might be hard to justify at first. There is no question that OJT is expensive. But how much does it cost if you don’t provide some form of on-the-job training? If you think OJT is costly, I suggest you take an honest look at how much callbacks for simple mistakes cost. As you step up your OJT, your crews will start doing better work and make fewer mistakes. Fewer callbacks equate to higher profits.

I suggest you allocate a portion of your proceeds to OJT. It might be hard to do at first, but you will likely come out ahead if you are in business for the long haul. Build OJT into your pricing, plan on OJT, and invest in your workforce.

If you’re still skeptical, consider how expensive it is to hire and onboard a new employee. Most employees appreciate learning new skills and getting better at their craft. A bit of training can go a long way, improving both the quality of your projects and employee retention.

Create a Clear Path for Advancement

The trade unions figured out years ago that people are often more willing to do a less desirable job if they know it’s not forever.

Heating and cooling projects are a perfect example. Let’s start at the bottom and work our way up. The least desirable job might be duct installation. Working in confined, dirty spaces, like attics and crawlspaces, takes its toll. It’s difficult, hot, and dirty work. If you work in HVAC, and this is what you do every day, I have massive respect for you, and I mean that sincerely. Hopefully, your company has a path for advancement, and after pulling ducts for a while, you get to move up to installing the furnace or heat pump itself. Installing the equipment is much cleaner but requires more knowledge. Hopefully, you got some OJT from your employer and now understand how to install and configure the equipment properly.

Perhaps the next step up the wrung is commissioning the equipment after it is installed. Modern HVAC systems need to be appropriately configured to achieve their rated performance. Refrigeration is a technical skill that also is part of this process.

Engineering the system and ductwork’s size and location requires even more experience and knowledge, especially if you are a performance-oriented business. The next level might include joining the sales team or moving into management.

You get the basic idea. Create a structure that encourages advancement through education and reward that advancement with cleaner work and higher pay.

Pay Well

Speaking of higher pay, we must create decent-paying jobs if we want the clean energy industry to grow. Many trades in the energy efficiency world don’t pay the same as other construction positions. We ran into this while trying to do quality home performance work. Worker bees, the folks you rely on to do labor, have choices. They can decide if they would rather dig a ditch, stand upright outside, or pull ducts through a dirty crawlspace on their stomachs. If the pay is the same, guess which job wins? Often, we lost laborers because of the challenging locations and tasks the projects required. If the people in the crawlspace make more money than the ones digging ditches, it might be easier to retain them.

We need to consider pay scales if we expect to grow the industry to the necessary capacity the policy folks are counting on. We need to provide compensation relative to the difficulty of the work. I don’t think we do a good job of this today.

Plant the Seed Early

We need youth to enter the trades. Many young folks today are conditioned to believe that a college education is a must before you enter the workforce. I can’t tell you how many people I know that graduate with a degree and tons of debt to go with it. I was one of these many years ago. Student loans are easy to get and hard to pay off. It took me over a decade to nibble away at mine.

Today, college grads are leaving school with six figures of debt and taking entry-level positions. Some entry-level jobs pay less than serving burgers.

We need to reach out to younger generations and propose the idea of trade schools and OJT in place of a college degree and debt. Want an example? HVAC techs. You can get a decent trade-level certificate as an HVAC tech in less than two years. Once you graduate, the earnings potential is there and waiting for you. I am talking about real money here. A six-figure starting salary is realistic. Contrast that to four years of schooling and $100k of debt to make $20 an hour.

We need to start at the high school and junior college level and let the young folks know there is more than one way to do things. While we are at it, let’s ensure we don’t leave anyone behind.

Include Everybody

There is no reason we can’t include all kinds of people in this new workforce. People of color, women, at-risk youth, the list goes on. We will need tons of new workers to make this effort effective. Race, economic status, or gender have nothing to do with capability.

Funding Is on The Way – Let’s Use it Well

Loads of federal funds are currently being allocated to workforce development. I have seen this before, and I wish I could say it was well utilized and effective. Hopefully, we have learned from our mistakes and will do a better job this time. We need to scale up fast and effectively to meet today’s challenges, not to mention the needs of tomorrow.

This article originally appeared on the EFCA blog and is reprinted with permission.

Earn CEUs

Earning CEUs on the BPA Journal is a member-exclusive benefit. Please log in to complete the quiz and earn them or join as a member today.