Feb 10, 2025

Indoor Air Quality for the HVAC Technician – Part 2

IAQ remains an essential but often neglected aspect of the HVAC industry—here's how you can diagnose and solve common issues.

By: Brynn Cooksey, Sr., CEM, CMS

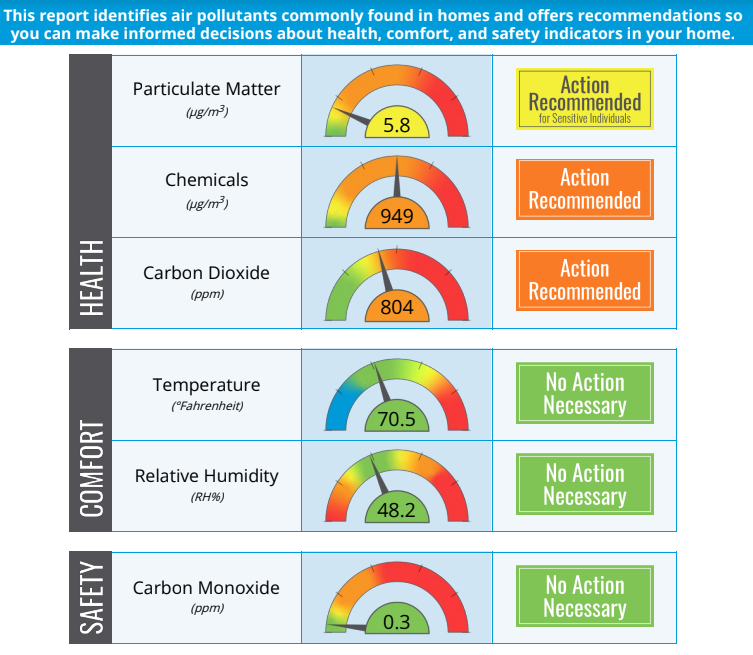

Part 1 of this article series discussed some common indoor air quality issues, how to measure them, and how to resolve them so customers can enjoy cleaner air. Part 2 continues with CO2, CO, humidity, and temperature issues.

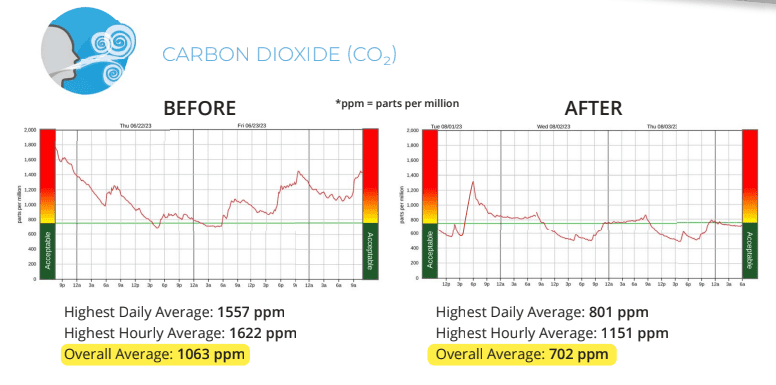

Carbon Dioxide

Another common IAQ issue is high carbon dioxide (CO2). Carbon dioxide is a gas that is naturally produced by combustion. The majority of CO2 in homes comes from the breathing done by humans and animals. According to a study by Portland State University of more than 300,000 tests performed with IAQ monitors, CO2 is the most common IAQ pollutant. The study concluded that 62% of homes tested had elevated action levels. The Environmental Protection Agency (EPA) has coined the term “sick building syndrome,” which expresses symptoms that include fatigue, headache, breathing difficulties, nausea, poor vision and itchy skin.

High CO2 has also been linked to poor work performance and reduced concentration from children in school settings. The EPA recommends a maximum concentration of 1,000 ppm; however, levels above 750 are still of concern. The higher level of carbon dioxide means that a significant portion of the air we breathe has been in someone else’s lungs; this is called the “rebreathed fraction.”

Higher carbon dioxide levels are directly linked to a building’s ventilation rate—tightly constructed buildings where ventilation was not a design consideration experience high levels of carbon dioxide. When building owners make strides to weatherize or reduce the energy consumption of their building, many of the weatherization tasks, such as air sealing, reduce the amount of natural fresh air that a building has available. Often, when weatherization work is performed, and ventilation is not a specific concern addressed with a mechanical ventilation system, indoor air quality becomes a more significant hazard due to the lack of fresh air for building occupants.

Carbon dioxide is also a byproduct of the combustion process. The HVAC technician should pay close attention to verify that the increase in CO2 is not coming from a back-drafting or poorly operating combustion appliance. We will discuss this more in the carbon monoxide section.

How to Control Carbon Dioxide

With carbon dioxide, “dilution is the solution.” Another age-old building science saying that helps the HVAC technician think about solving IAQ issues with ventilation is the saying “to eliminate, ventilate.” Like particles and chemicals, ventilation is another key ally in combating poor IAQ, namely carbon dioxide. As with the other parameters, ventilation will bring relatively fresh air into the structure, reducing the concentration of carbon dioxide. Some ventilation systems are set up with sensors that will detect increasing levels of CO2, activating the ventilation system. This technique helps reduce the energy consumption needed to ventilate the structure properly. VOCs and CO2 are frequently found together in tight homes that do not have proper ventilation. The sources that generate CO2 are relatively small, but CO2 will build up over time.

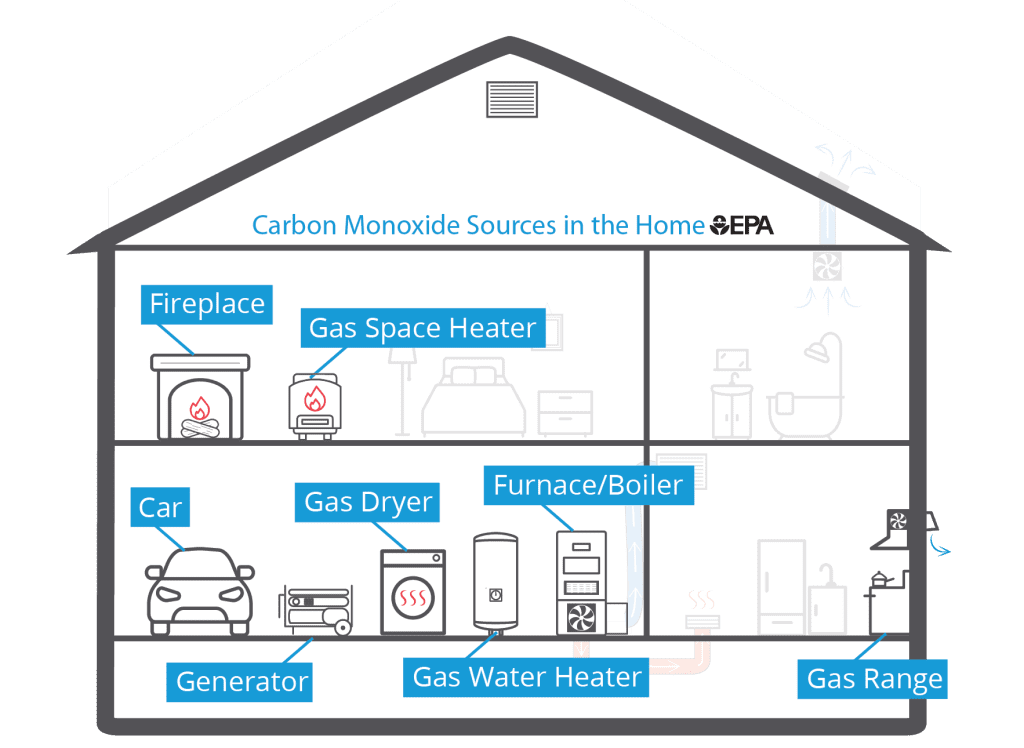

Carbon Monoxide

Carbon monoxide (CO), also called the “silent killer,” is given this name due to its features. Carbon monoxide is an odorless, colorless, tasteless, poisonous gas that is impossible to detect without instrumentation. It results from incomplete combustion and it does not take large doses of exposure to be harmful. Regarding IAQ issues, CO can be generated in the home and inhaled by the building occupants. If carbon monoxide is elevated, notify the building owner immediately, and based on your training and company procedures, help the client understand its hazards. Carbon monoxide bonds to the blood at a rate about 200 times faster than oxygen does. When exposed to it occupants may complain of headaches, dizziness, chest pain, nausea, and other flu-like symptoms, and if exposed to higher levels, death.

The permissible level of carbon monoxide varies based on the agency and authority having jurisdiction (AHJ). Follow local codes and company policies to comply with local rules and regulations. It is important to note that carbon monoxide levels may also spike during everyday activities like cooking, so be sure to understand the situation regarding elevated CO levels. When unrelated to an event like cooking, low levels of consistent carbon monoxide correlate with an improperly operating combustion appliance or a CO source being brought in from outdoors, like a generator or a nearby vehicle.

How to Control Carbon Monoxide

When evaluating combustion appliances, the HVAC technician should ask two questions related to CO that must be verified: Are the combustions supposed to be vented outside and are they producing unsafe levels of carbon monoxide? These two essential items to check circle back to source control, the best defense for healthy IAQ. A properly operating vented combustion appliance should not generate unsafe levels of carbon monoxide. The appliance should be removed from service if it creates an unsafe condition. Vented combustion appliances must be installed correctly to avoid the possibility that the combustion gases come back and enter the home. Other appliances that vent into the people’s space, like gas ranges or ovens, must be serviced consistently to verify that the CO levels produced are below acceptable codes and standards. Additionally, combustion appliances that vent directly into the building should be accompanied by an appropriately sized and working exhaust fan that takes the harmful pollutants to the outdoors.

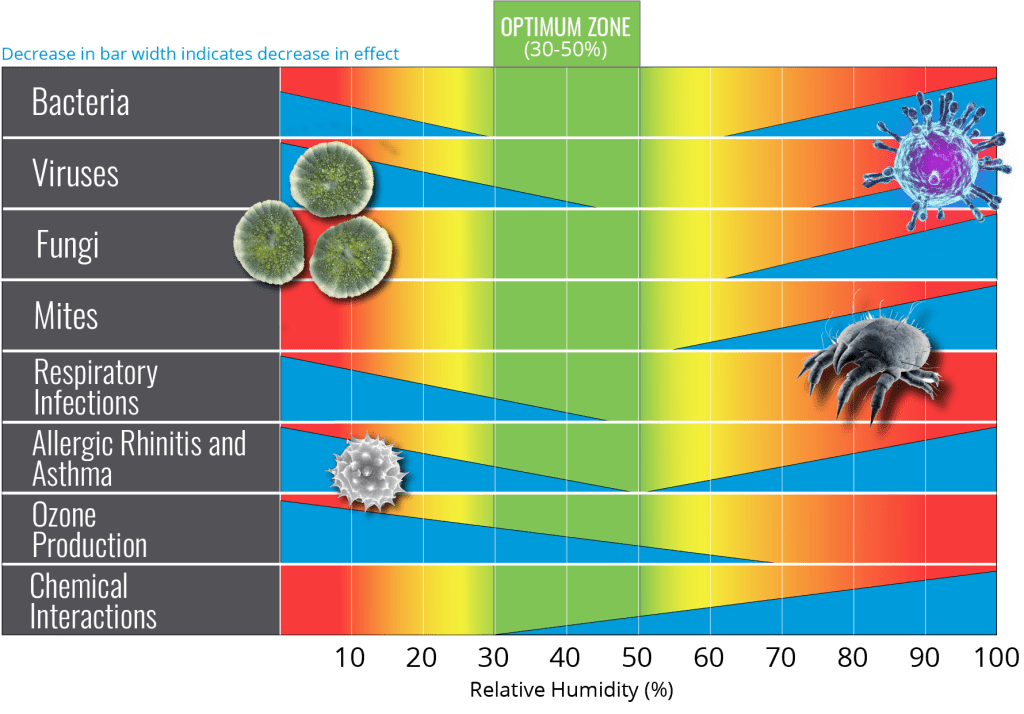

Humidity

It is important to note that humidity or dampness is considered the single greatest source of IAQ issues and is often only considered a comfort issue. Improper humidity levels are another IAQ and comfort concern. Depending on the climate region and the mode of the HVAC system, humidity or lack thereof can have serious consequences, such as poor occupant comfort and health issues, and the durability of building materials. Humidity makes up much of the total comfort that building occupants experience. “Relative humidity” is defined as the amount of moisture contained in the air compared to the amount of moisture that the air can hold. This ratio, expressed as %RH, is a critical IAQ parameter that every technician should check.

According to American Society of Heating Refrigeration and Air-Conditioning Engineers (ASHRAE), humidity levels should be between 35%–60%. Personal comfort is the best in this range but has other benefits. The humidity chart below shows the optimal humidity zone. Bacteria, viruses, fungi, mites, respiratory infections, allergic rhinitis, and asthma occurrences are minimal when humidity is in the optional zone. A level under 35% can cause occupant complaints of dryness, including itchy skin, increased allergy symptoms and a host of other problems.

Excessive humidity levels also wreak havoc on the building and pose other health problems. Moist air or relative humidity levels above 60% create ideal conditions for mold to colonize and grow. Testing humidity is critical and should be done with every service call. As you work with your clients, you may find them trying to cope with humidity problems. Look for stand-alone dehumidifiers and humidifiers. These devices may indicate that the humidity levels are not in the optimal range and that the occupants may be experiencing some discomfort.

How to Control Humidity

Many issues cause humidity problems and source control is the key, as is the case with many other IAQ issues. In cold climates during the winter months, dryness or a lack of humidity may be the complaint. As a forced air system warms the air, its relative humidity is reduced. Dry air has many side effects, including dry skin, eyes, electrostatic discharge (static shock) as well as other issues. To combat dryness in a structure, a humidifier adds moisture to the air to increase the relative humidity. A humidifier can be used alone or with a forced air system. In either case, moisture is introduced into the environment to increase the relative humidity. Low humidity levels in the building can indicate that the building shell is excessively leaking. High air infiltration rates (air leaking into a structure) allow air from the outside to leak in. This cool dry air from outside, which may have low relative humidity to start, replaces the building’s air several times per hour. As a result, the building may require a humidifier since the conditioned and treated air was pushed out of the structure.

High relative humidity is not ideal either. During the summer months, the air conditioning system is responsible for maintaining the proper humidity levels in the building. High relative humidity can come from internal sources, such as bathing or cooking, and it can come from external sources, such as bulk water (water for large leaks), and foundation issues, such as high hydrostatic pressure on foundation walls. Source control is critical for controlling high relative humidity. If you stop the leaks, you stop the issue of high relative humidity.

In addition to source control, an appropriately sized and maintained air conditioner will help keep humidity levels in the optimal range. Oversized air conditioners lack the runtime needed to dry the air, and as a result, the relative humidity will remain high enough to reach uncomfortable levels. Customers may report that the air is “clammy,” meaning it feels moist to the skin. Poorly maintained air conditioning systems will also have the same effect. High relative humidity comes with challenges, and humidity ranges outside the optimal range also contribute to many of the same issues as dry air. To cope, many people may purchase a dehumidifier to reduce the moisture within the structure. As with humidifiers, dehumidifiers can be standalone or operate in conjunction with the HVAC system. Dehumidifiers work to reduce the humidity levels of the air in the same manner a traditional air conditioner would remove moisture.

Temperature

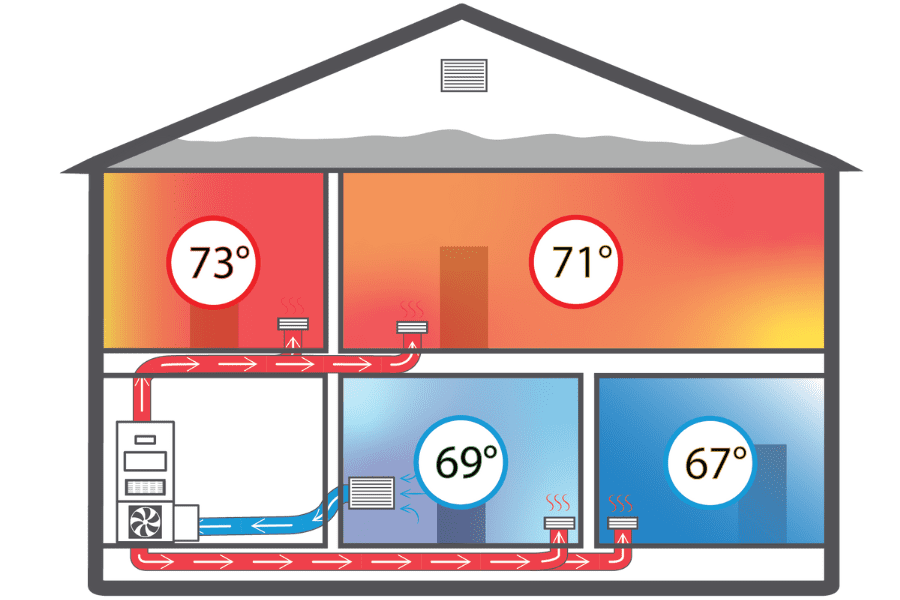

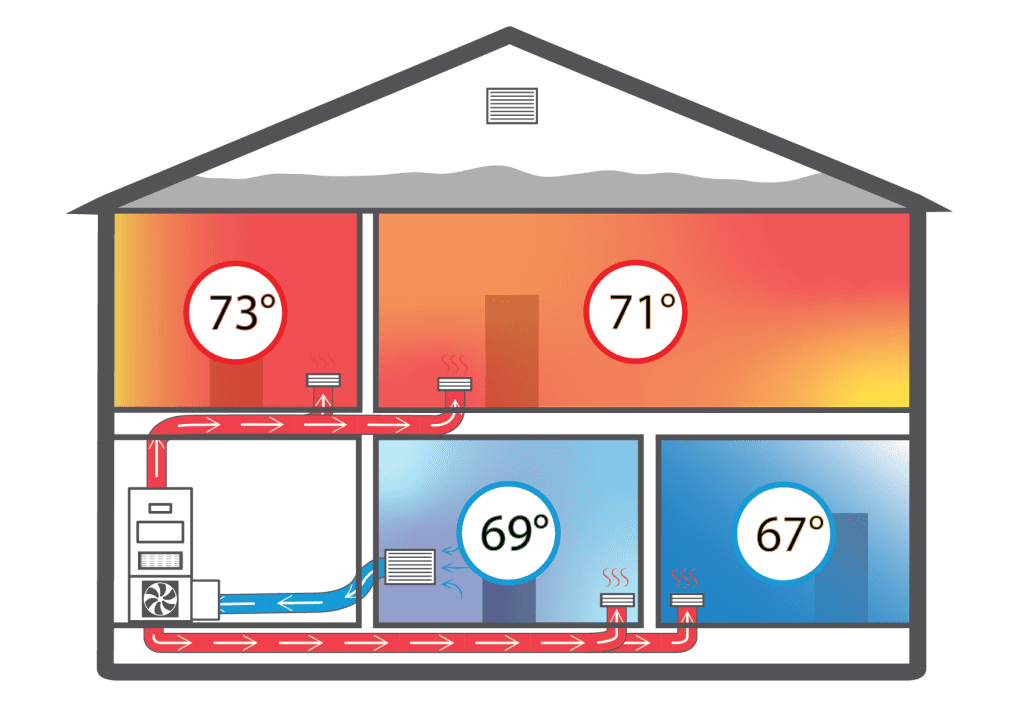

Many individuals do not readily determine temperature as an IAQ concern, yet it is the chief IAQ component. When measured from the IAQ standpoint, temperature is a crucial parameter to determine if the HVAC system is operating correctly or if there are building issues causing a temperature issue. According to ACCA’s Manual J (Residential Load Calculation), heating systems are designed to maintain a temperature of 70°F and cooling systems 75°F. Many customers cope with an unbearable room or area of their home. A temperature measurement may reveal several issues that can be resolved. A temperature measurement can indicate hot-laden air coming into the home from an unwanted area like an attic. Temperature measurements could also help to discover disconnected or leaking ducts. In some situations, ducts need to be insulated, and taking temperature measurements may reveal that they were never insulated or that the insulation is degraded. Testing may further reveal that a building has deficient insulation in the building shell or that it needs to be professionally air sealed.

How to Control Temperature

Controlling temperature starts with the fundamentals of designing and performing a proper heat loss/heat gain calculation. The complement to every load calculation is a good duct design, with the ducts being appropriately sized, sealed and balanced. Other complaints with temperature can be solved by zoning different areas using airflow or separating equipment dedicated to a specific area to improve comfort. Lastly, temperature complaints may be caused by the building itself through excessive air leakage or poor insulation. Without testing temperature, many of the items may be overlooked.

Test In—Test Out

IAQ remains an essential but often neglected aspect of the HVAC industry. Using this straightforward procedure to diagnose and solve IAQ issues can help both techs and their customers. Test in and test out. What is measured is what is changed, so measuring IAQ issues on every call will help clients understand that they have an IAQ problem that can be fixed.

Very often, one particular issue may show up as several IAQ parameters. For example, if a family recently just cooked dinner and you tested for IAQ issues, you may find elevated particles, carbon monoxide, humidity, temperature and carbon dioxide. Understanding IAQ may help identify the cause of elevated levels and whether or not a specific activity contributed to the readings. As solutions are crafted, carefully research products being used to verify that they are “safe” and “effective.” To deliver the best possible results and total customer satisfaction, “test out” to verify that the solution created an improvement.

Remember that some solutions may take weeks to improve the air quality, so consider this when conducting post-retrofit testing. Customer education is also essential. Avoid making claims to improve the client’s health or to cure them. Remember, the solutions will “improve the air quality,” meaning overall occupant well-being.

All images provided courtesy of Air Advice. This article originally appeared in the RSES Journal and is reprinted with permission.