Sep 13, 2023

Meet David Gibson, Maine’s Fossil Fuel Eliminator

It is Director of Energy David Gibson’s primary responsibility to make sure that the College of the Atlantic is off fossil fuels by 2030.

By: Macie Melendez

In 2017, the College of the Atlantic (COA) made a commitment to transition their campus off of fossil fuels by 2030. It is Director of Energy David Gibson’s primary responsibility to make sure that happens.

COA is an innovative and experimental college dedicated to the study and practice of human ecology (the relationship between humans and their environments). Located in Bar Harbor, Maine, it has a total of 350 students—all of whom study human ecology in a different way. Every student at COA designs their own major and builds their own curriculum. Some students are interested in working in the energy sector and many of them want to put things into practice—like learning how to fix the places they are living in or their family home, for example.

“Having a focus on fossil fuel elimination has been great,” says Gibson. “While that is my primary responsibility, I am also tasked with teaching half-time.” For Gibson, that means teaching one class during each of the college’s three terms, as well as working with interns during the summer. “I’ve taught building science and energy auditing, green building techniques (a USGBC LEED-focused class), an energy education course for teachers, and a hands-on energy practicum,” he says.

During his hands-on courses, he and his students contributed to extensive energy improvements on and off campus, which also gets them closer to their zero fossil fuel goal. These improvements include switching buildings off fossil fuels entirely, insulating attics and basements, and installing heat pumps and heat pump water heaters.

More specifically, Gibson and his students have insulated 3 attics, installed vapor barriers in 4 basements and installed low-flow showerheads both on and off campus, while they’ve overseen contractors who have insulated 24 units of housing, installed heat pumps in 25 buildings, and installed 20 heat pump water heaters.

“The goal of being fossil-free by 2030 was student driven,” says Gibson. “COA was the second college to divest from fossil fuels, and it’s the ‘greenest’ college in the country,” says. Which is why, when he started, he was surprised at the lack of insulation in the college’s buildings. Over the last two years, his efforts have reduced the COA buildings’ greenhouse gas emissions by approximately 52%.

COA can house about half of its students on campus and there are 18 off-campus housing options. There is also some staff housing.

“We have a simple three-step process for making things energy efficient,” says Gibson. “Air sealing, insulation, and electrification.” To offset any electric use, they are also installing solar. “Starting this fall, we’ll be able to provide most of the campus’ electricity through a local solar farm.”

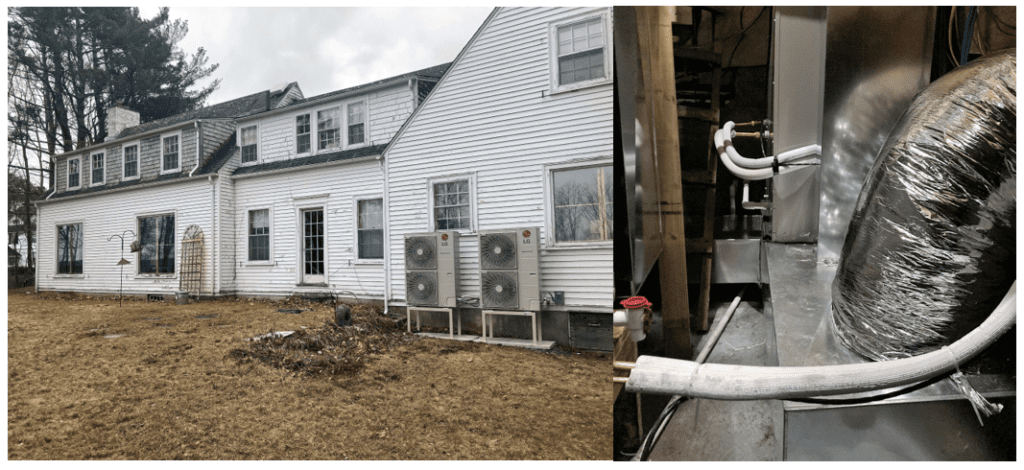

One of Gibson’s recent energy improvements was at the COA’s Witchcliff building, in which he had a contractor replace a 38-year-old oil furnace with a pair of ducted heat pumps. This change saves 1,500 gallons of kerosene a year, or $7,500 a year (at an estimated $5/gallon). In its first six months, the heat pump used 7,500 kWh of electricity more than the year prior, increasing electric costs by about $2,000, which brings the building to a net savings of about $5,500 per year. “This $35,000 system will pay for itself in less than 7 years,” says Gibson.

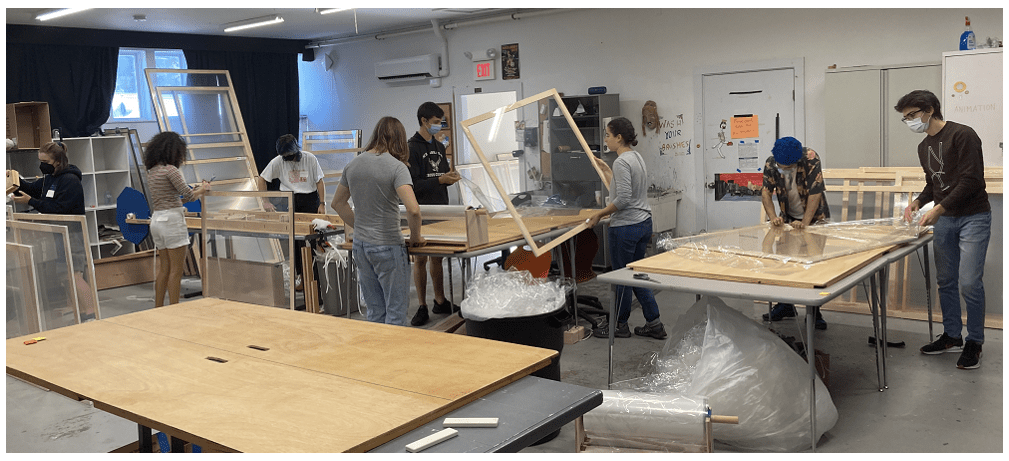

Another recent project allowed Gibson to host a WindowDressers workshop in which 80 students, faculty, staff, and community members volunteered more than 300 hours building insulated window inserts. WindowDressers is a volunteer-driven non-profit organization dedicated to helping Northern New England residents reduce heating costs by lowering the amount of heat loss through windows.

“We made 350 of them in a week,” says Gibson. Window inserts ended up being installed in campus buildings and some of the dorms, and Gibson estimates that those inserts save approximately $11,000 a year in heating costs.

Additionally, Gibson and his students participated in an Efficiency Maine pilot program to install the first commercial split system heat pump water heater in the state. This system provides all the domestic hot water for Blair Tyson’s sinks, showers, and laundry. (Blair Tyson is a series of seven connected townhouses, each of which is home to eight COA residents.) Efficiency Maine paid for 40% of the installation cost and this system is estimated to save 2,500 gallons of heating oil each year, which amounts to approximately $3,300 per year in net cost savings.

Gibson has no plans of slowing down—if anything, he’ll be doing more projects in the future. When we spoke, he had just received approval to convert an old laboratory in the COA’s Arts and Science building into an energy classroom.

“With this space, we would like to build WindowDressers year-round, set up demonstrations of different types of insulation, host community workshops, have a secure place to store our energy auditing equipment, and have a classroom space for all types of energy classes,” he says.

Will he get COA to fossil free in the next 7 years? We’ll all just have to wait to find out. (But our odds are on Gibson.)