Dec 21, 2022

Calculating House Volume for Blower Door Tests

Measuring the volume of something is straightforward; however, a modern home is rarely built as a simple box.

By: Randy Williams

A blower door is designed to measure the volume of air moving across the blower door fan at a specific pressure difference between inside and outside the home. In the U.S., blower doors are set up to measure the volume of air in cubic feet per minute (cfm), and the pressure differential is measured in pascals (50 pascals is the standard for residential construction). One of the more common metrics used to express air leakage in a home, however, is air changes per hour (ACH), and the only way we can calculate that metric is by measuring a home’s volume.

Measuring the volume of something is straightforward: length times width times height. The problem is that a modern home is rarely built as a simple box. There are crawlspaces and basements, inside and outside corners, and convoluted roof designs that all may or may not be included in the calculation. The first step is to understand what spaces are included, then we can measure and calculate the home’s volume.

The most recent energy code from the 2021 IECC requires all blower door testing to be performed in accordance with either the ANSI/RESNET/ICC 380, ASTM E779, or ASTM E1827 standard. This article will be based on the methods for calculating volume specified in ANSI/RESNET/ICC 380.

This article is based on the methods specified in ANSI/RESNET/ICC 380, which uses measurements for floor area from the exterior finish of the building. That means the author will need to add the thickness of the exterior walls to measurements like the one he is taking here.

Conditioned Floor Area

While calculating the volume of a space can be done simply by multiplying length times width times height, we start by measuring the conditioned floor area, or length times width. The 380 standard uses the older ANSI Z765 standard for calculating square footage of a home, which is measured from the exterior finish of the building. All exterior and partition walls are included in the floor-area calculation. A basement might or might not be included in the conditioned floor area; if it is serviced by the heating and cooling equipment, the space is included in the conditioned floor area.

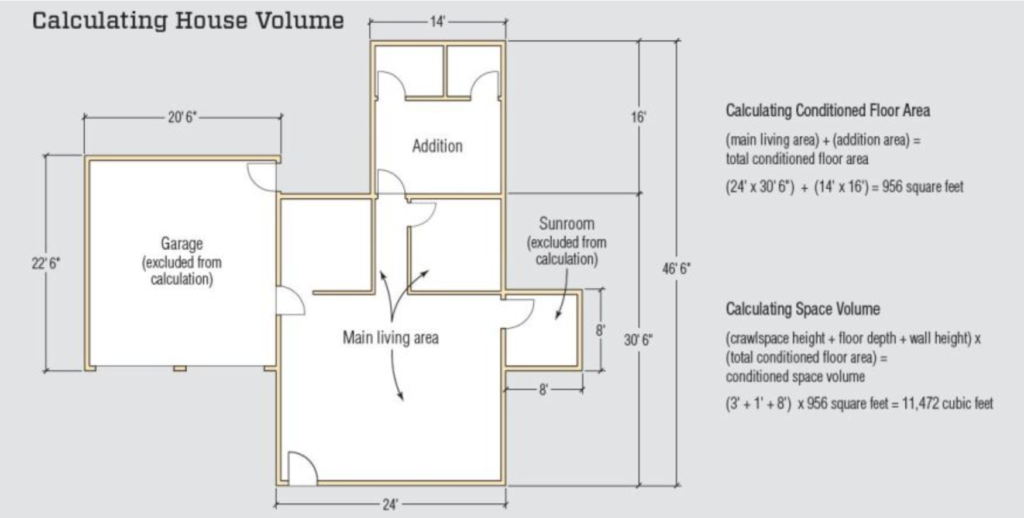

Floor areas that are excluded from the conditioned floor area are those of attached garages (even when they are conditioned), thermally isolated sunrooms, attics (even if conditioned), crawlspaces (even if conditioned), and unconditioned basements. So, for example, in the simple floor plan shown below, the attached garage and sunroom would be excluded from the conditioned floor area. This leaves the main area of the home, 24 feet by 30 feet 6 inches, and the addition, 14 feet by 16 feet, for a total conditioned floor area of 956 square feet as measured from the exterior of the building.

Per ANSI/RESNET/ICC 380, the attached garage and sunroom would be excluded from the conditioned floor area. This leaves the main area of the home, for a total conditioned floor area of 956 square feet as measured from the exterior of the building.

Conditioned Space Volume

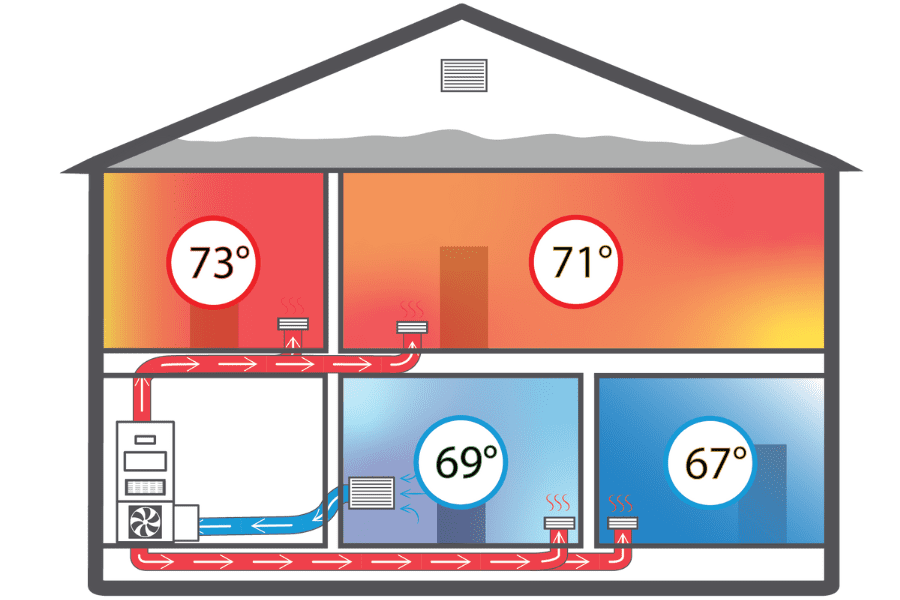

Once we know the conditioned floor area of the structure, we can begin measuring the height to calculate volume. This volume calculation will usually include any space between two floors; for example, the space between a first and second level would be included as long as both floors are conditioned. According to the 380 standard, a space is considered “conditioned” if the evaluating party has either:

“Obtained an ACCA Manual J, S, and either B or D report and verified that both the heating and cooling equipment and distribution system are designed to offset the entire design load of the volume; or

“Verified through visual inspection that both the heating and cooling equipment and distribution system serve the volume and, in the judgement of the party conducting the evaluations, are capable of maintaining the heating and cooling temperatures specified by the Thermostat section in the Building Component Column of Table 4.2.2(1) of ANSI/RESNET/ICC 301.”

One complication to the 380 standard is that a conditioned attic or crawlspace, which is not ordinarily included in the conditioned floor area, may be included in the conditioned space volume if a door or hatch is opened to the space during the blower door test.

Using the simple floor plan (above) as an example, if that home had a conditioned crawlspace or basement, the volume of that space would be included in the overall volume of the home. So, if the home had a 3-foot-deep crawlspace, a space between the crawlspace and main level of 1 foot, and 8-foot flat ceilings for the main level, the calculation would be: 12 feet (3 feet + 1 foot + 8 feet) x conditioned floor area of 956 sq. ft. = 11,472 cubic feet of conditioned space volume.

What happens if there is a vaulted ceiling or some other complicated roof detail somewhere in the home? That space would be included in the conditioned space volume. Measuring the volume of a simple vault or cathedral ceiling isn’t difficult, unless dormers or some other convoluted rooflines are also included in the vault.

Often, calculating the volume of a home will take much longer than performing the blower door test; when a home is complicated, I usually perform the math to calculate volume in my office after performing the test. On very complicated homes, I may use architectural software to aid in the calculation.

Alternatives to the Standards

Standards are the recommendation; I personally do not follow all of the 380 standard. For example, I disagree with measuring the structure from the exterior. In my heating-dominated climate, it’s common for the main air control layer or air barrier to be located on the warm-in-winter side of the exterior wall and roof assemblies. To me, it makes sense to measure area from the interior. (It is also difficult to measure the exterior of the home during the winter months when snow impedes moving about the outside of a home.) The code officials I have discussed this with agree with the thinking and allow the variation of the standard. On the downside, measuring from the interior does result in a smaller volume, which makes it more difficult to pass the blower door test.

If you want to deviate from the standard, have a discussion with your local authority having jurisdiction and be consistent with your practices.

How I Measure

I start my measuring process by making a simple sketch of the home’s floor plan. This can be done from either the interior or the exterior. Moving around the home also gives me the opportunity to check for any concerns before testing. After producing a sketch, I begin measuring.

I prefer to use a laser measuring device, but I sometimes will also use tape measures and measuring wheels. Lasers work well if you have a line of sight between the two areas being measured; occasionally, it will be necessary to add measurements of several different rooms together to achieve a total length. I do round measurements to the nearest quarter foot.

Once I map the floor plan, I measure the heights of the various spaces. Homes with flat ceilings are easy; to accurately calculate the volume of a complicated home, however, you may be required to calculate volumes of spaces with triangular, trapezoidal, or curved sides.

It is possible to use a set of architectural plans to calculate the volume. Or you may be able to import a digital copy of the house plans into a software program, which then can be scaled to allow for accurate volume calculations. This can speed testing, allowing you to calculate the volume off site. But it’s not uncommon for a home to vary from the plans, so be sure to verify the measurements at the time you conduct the blower door test.

The architect or designer may be able to calculate the volume for you. I had a discussion a while ago with Alexandra Baczek, an associate at Steven Baczek Architect, on using software to calculate volume. She said, “We have used SketchUp in the past for the purpose of translating volume metrics to energy consultants. SketchUp has the ability to quickly generate the volume of a model, but like anything, that metric is dependent on the accuracy of the model. For a simple house, it’s pretty easily achieved; for a more complicated house, the complexity is relative.” Remember, whether you or a designer calculate volume from the plans or a software model, you need to back that up by confirming measurements on site to verify the accuracy of the calculation.

Local Code Variations

Be sure to check any local code requirements when it comes to calculating a home’s volume for blower door testing. The energy code in Washington state, for example, caps the ceiling height used for calculating volume at 8.5 feet. This includes the height of any cathedral ceilings. It is easier to pass a blower door test in a home with a large volume than in smaller homes. I believe this is Washington’s attempt to level the playing field.

The ACH50 Calculation

Once you’ve measured the volume of the home and run the blower door test (which will normally be shown as cubic feet per minute of airflow moving across the blower door fan), you can calculate the air changes per hour at 50 pascals of pressure (ACH50), which is what the code is looking for as the pass/fail metric of a blower door test. The formula is the rate of airflow in cfm x 60 minutes in an hour / volume of the home = number of air changes per hour.

As an example, a home had a blower door test of 750 cfm and a calculated volume of 12,000 cubic feet. Using the formula, 750 cfm x 60 minutes / 12,000 cu. ft. = 3.75 ACH50. This home would pass the blower door test in areas of the country where the test result must be 5 ACH50 or less but not where the requirement is 3 ACH50 or less. It’s important to know the requirements in your area.

Air Changes Vs. Airflow

While ACH50 is the metric required by code, it is not necessarily the best metric for determining the tightness of a structure. A home does not leak in its volume; air leaks happen on surfaces, specifically the exterior shell. To demonstrate, consider the calculations for the smallest and largest homes I’ve tested to date:

The smallest was a 696-sq.-ft. home built in 2018. In a code-

required blower door test, the volume of the home was calculated at 6,333 cu. ft. with airflow at 316 CFM50. This home barely passed the blower door test at 2.99 ACH50. (Code requires 3 ACH50 or less in my area.) To put that level of tightness in perspective, a clothes dryer and bath fan operating at the same time in this home might be capable of producing a negative pressure of 50 pascals, the same as a blower door test. The home is tight.

The largest home I’ve tested was a seasonal log cabin just over 5,000 sq. ft. with a cavernous volume of 99,076 cu. ft. The interior peak of the main cathedral ceiling was 25 feet high and the structure had a 4-foot-high conditioned crawlspace. The crawlspace is not included in the conditioned floor area of the home but is included in the conditioned space volume. This blower door test was part of an energy audit. The home’s leakage rate was 5,306 CFM50, or 3.21 ACH50.

The air change rates of the two structures are similar, but with very different airflow rates. There are other metrics for showing different leakage rates of a home; the best, in my opinion, is cubic feet per minute at 50 pascals per square foot of surface area. I’ll discuss that another time.

Conclusion

For the vast majority of blower door tests I conduct, I spend much more time calculating volume than performing the test. The final air-changes-per-hour calculation will only be as accurate as the volume calculations. Understanding what areas are and are not allowed to be included in the volume of a home also plays into the test’s accuracy. The ANSI/RESNET/ICC 380-2019 standard is currently the best source of information on performing blower door testing for code compliance.

This article was originally published in The Journal of Light Construction and is republished with permission.

Earn CEUs

Earning CEUs on the BPA Journal is a member-exclusive benefit. Please log in to complete the quiz and earn them or join as a member today.