Jun 6, 2022

The Sweet Spot Between Energy Efficiency and Material Health

There is growing awareness that the buildings where we live and work can affect our health. Daylighting, acoustics, air flow, and the very materials we use all have the potential to impact the health and wellbeing of building occupants. When we think about chemical exposures in the built environment, our minds often go directly to indoor air quality.

By: Ryan Johnson and Rebecca Stamm

There is growing awareness that the buildings where we live and work can affect our health. Daylighting, acoustics, air flow, and the very materials we use all have the potential to impact the health and wellbeing of building occupants. When we think about chemical exposures in the built environment, our minds often go directly to indoor air quality. After all, we spend most of our time indoors, and many harmful chemicals tend to be present at higher levels in indoor air than in outdoor air. For this reason, solutions tend to focus on higher air exchange rates and more efficient filtration. While these are essential considerations to ensuring our buildings are healthier spaces, the most efficient way to avoid exposure to harmful chemicals is by eliminating them from our buildings altogether.

Figuring out what chemicals are typically present in building products is challenging. While there has been great progress in transparency through the publication of Health Product Declarations and Declare labels, most building products do not come with documentation that fully discloses all of the chemicals that they contain. Even when we can identify the chemicals used to make these products, making a safer selection can still be challenging.

Why Materials Matter

Chemicals used in the built environment are linked to health impacts like asthma, cancer, and developmental disorders. They can even weaken our immune system. For instance, a recently published literature review highlights how multiple chemical exposures—including chemicals commonly found in building products—may make us more susceptible to severe disease resulting from respiratory infections such as COVID-19.

You may have heard about volatile organic compounds (VOCs), chemicals that off-gas from building materials. While it’s important to reduce exposures to VOCs, these are not the only hazardous chemicals found in the built environment. Furthermore, air is not the only way we are exposed to chemicals. For example, some chemicals end up in household dust and linger there. Some of these can be absorbed through the skin or ingested. Children can be exposed to chemicals, such as flame retardants, through breastmilk, or even prenatally through the placenta.

We may expect regulations to protect us from the most harmful chemicals. While chemical regulations do exist, they are generally insufficient to protect us from the dangers posed by toxic chemicals. In the US, chemicals are regulated under a framework that generally requires evidence of harm before restricting their use. Moreover, even when we have significant understanding about chemical toxicity, the restrictions on those chemicals can be insufficient. Take for example asbestos and lead, both widely known to have harmful health effects. Until recently, asbestos was still quite common in roofing materials. Lead, which is not considered to have any safe level of exposure, can still be used in pipes and other plumbing fixtures that are labeled “lead-free” and deliver potable water to our taps.

The good news is that there are some simple ways to select building materials that use fewer harmful chemicals. In fact, when it comes to insulation, healthier materials can also be cost-effective and still meet energy efficiency goals.

Insulation

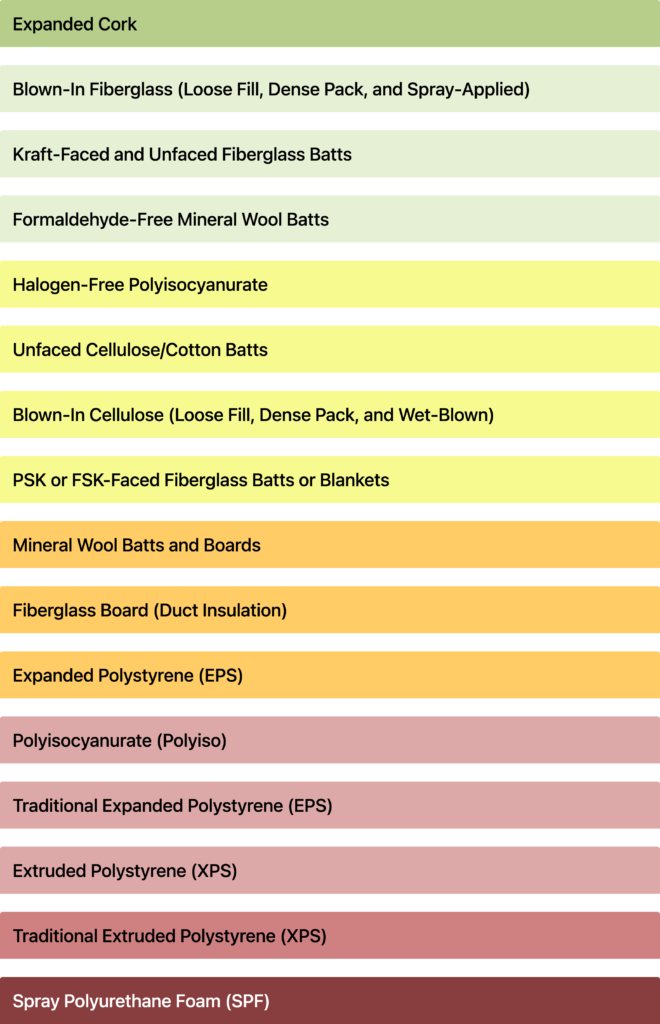

While it is always preferable to choose products with full content disclosure, as noted above this is not always feasible. In the absence of full disclosure, Healthy Building Network (HBN) has developed Product Guidance to help people select materials that are generally better for public health and the environment. To develop this guidance, we review product literature such as safety data sheets, patents, peer-reviewed literature, and transparency documents. We determine the chemicals of concern present within each product category, and then rank product types based on their typical content and hazards. In addition to considering chemicals that building occupants and installers may be exposed to, we consider exposures that may be unique to people manufacturing the products and environmental emissions that can affect communities living nearby.

The resulting Product Guidance allows users to quickly compare product types within a category. Products in green are typically the best options, whereas products at the bottom of the spectrum, in red, are to be avoided. Those in between provide intermediate options. Instead of simply a good and bad designation, this allows for a step-up approach to choosing “better” products. Our Product Guidance tools are freely available on the HBN website.

Let’s break down how we apply this to insulation.

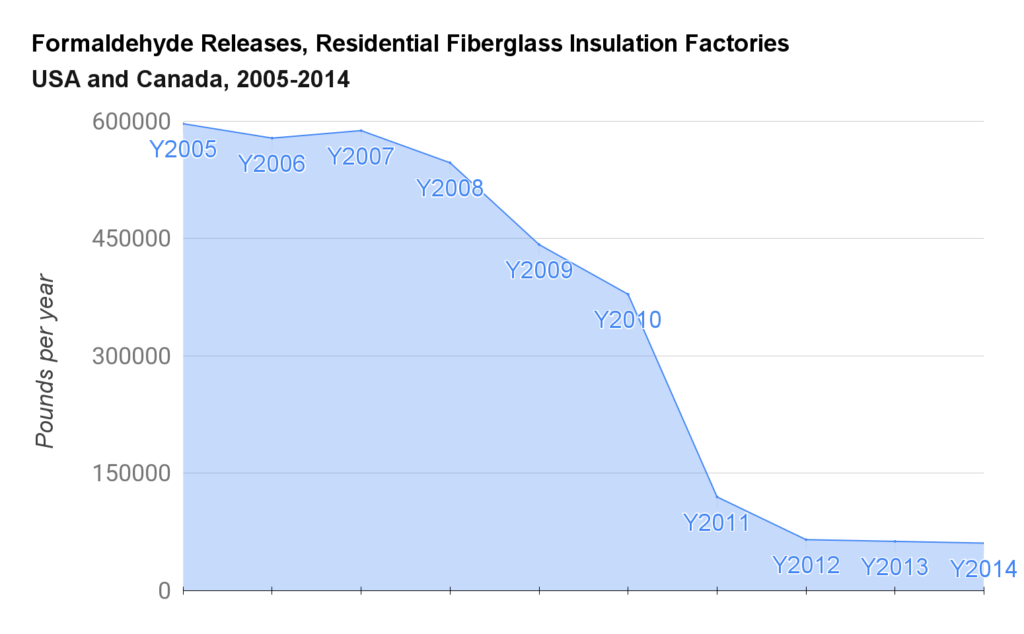

Many fibrous insulation products use formaldehyde-based binders. Binders are substances that are necessary to hold the fibers together into the desired shape, like batts or boards. These binders commonly emit formaldehyde gas, a known carcinogen that’s also associated with a number of additional health effects. While formaldehyde-based binders have been removed from fiberglass batt insulation, they are still commonly used in other types of fibrous insulation products.

Flame retardants are added to plastic foam insulation in order to meet flammability requirements. Most commonly, these are halogenated flame retardants. Chemicals in this class can be persistent in the environment—meaning they stick around and don’t easily break down—and are linked to cancer and a number of other health effects.

Spray foam contains chemicals called isocyanates, which are potent respiratory sensitizers and a leading cause of work-related asthma. They are the primary reason that people applying spray foam must wear heavy personal protective equipment, including respirators, which is not a fool-proof method to avoid exposure. Spray foam also contains those halogenated flame retardants mentioned above, along with other toxic chemicals. In addition, standard closed-cell spray foam formulations contain chemicals that contribute significantly to global warming.

Because of these and other considerations, at the end of the day our safer insulation recommendations are:

- Prefer fiberglass, formaldehyde-free mineral wool, or cellulose insulation.

- If board insulation is required, prefer expanded cork, halogen-free polyisocyanurate, or rigid mineral wool insulation.

- Avoid foam insulation, whether board or spray-applied, whenever possible.

- Use mechanical installation methods, such as fasteners, to avoid unnecessary use of adhesives.

A more detailed summary of this guidance is available on our Product Guidance page for insulation.

Combining Healthier Material Guidance and Energy Efficiency Considerations

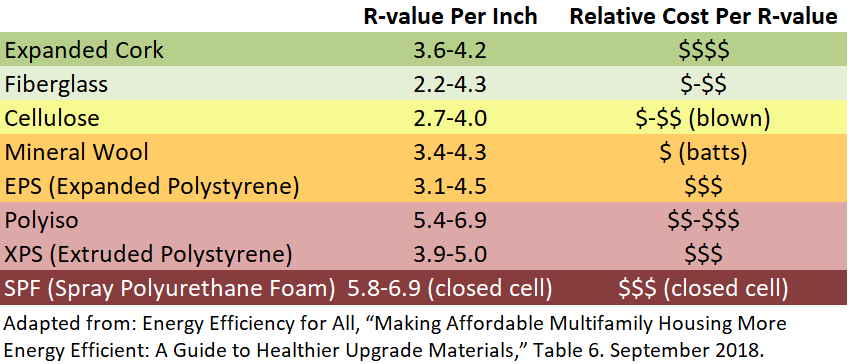

How does this guidance line up with energy efficiency and cost considerations? Several years ago, we teamed up with the National Resources Defense Council (NRDC) and Energy Efficiency for All (EEFA) to look into this question. The table below is a simplified version of an analysis that we conducted for that report.

While the top ranked product, expanded cork board, is expensive and may have limited availability, some of the best product types in our material health analysis also are the least expensive. Commonly used fiberglass and cellulose insulations are both placed near the top of the Product Guidance ranking and also have the lowest installed cost for a given R-value. While the R-value per inch is higher for many foam products, the R-value per dollar is not. This means that most foam insulation products cost more to achieve a given R-value relative to products ranked higher on the spectrum. While those less hazardous products at the top don’t function as air barriers, they do leave room in a budget for the addition of an air sealing material.

Another advantage of this Product Guidance is that it offers some flexibility in selecting healthier materials. For instance, space limitations may prevent the use of some of the highest ranked materials to achieve a given R-value, but project teams should still be able to move toward a less hazardous material. Remember, any step up the spectrum is a move in the right direction.

Sealants

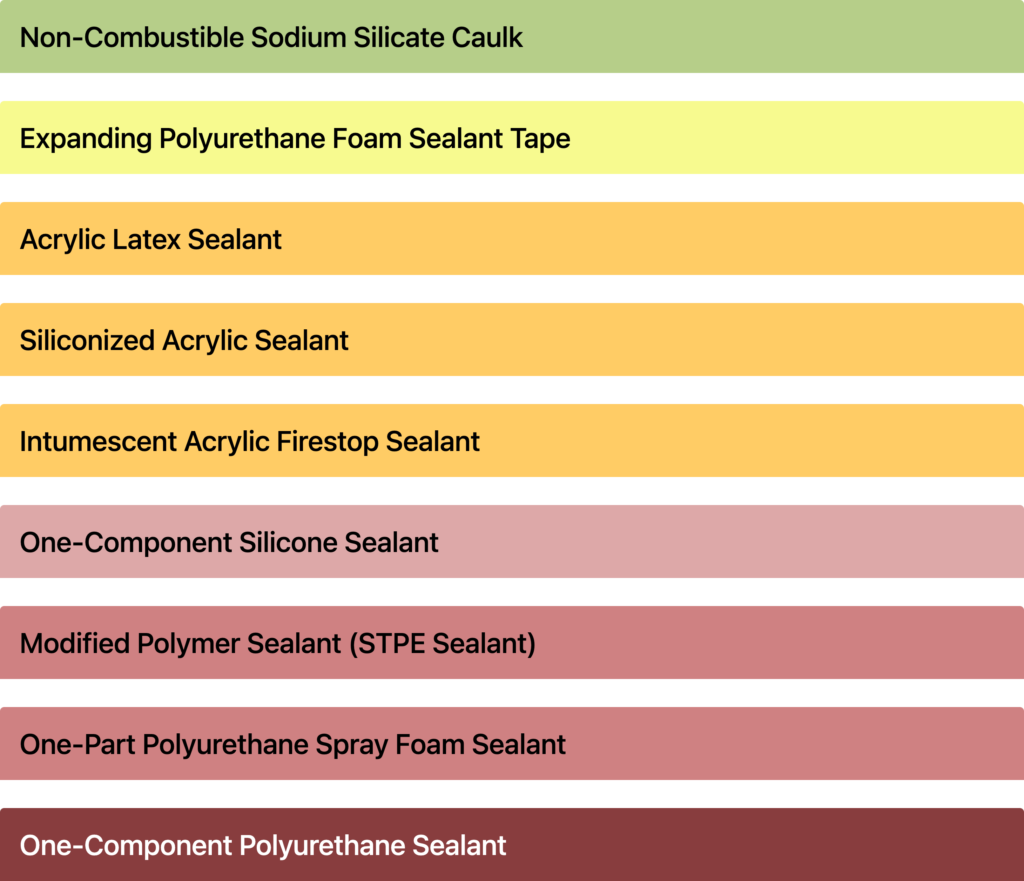

Many of the chemicals of concern found in sealants are similar to those in insulation. The figure below is a simplified version of our Sealants Product Guidance.

Similar to our guidance for insulation, more chemicals of concern are found near the bottom of the spectrum. In addition, several types of sealants can contain plasticizers—chemicals that are used to make rigid plastics more flexible. Some of these plasticizers, known as phthalates, mimic hormones in the body leading to various negative health outcomes. They have been associated with obesity and diabetes, harming the reproductive system, and numerous other adverse health effects. Silicone sealants contain small amounts of chemicals that are persistent and accumulate in the environment, and are also associated with a number of known and suspected human and environmental health effects. Polyurethane foam sealants that are reacted on site have similar concerns to those of spray polyurethane foam insulation.

Our general recommendations for selecting sealants are:

- Prefer caulk-type sealants over spray foam sealants.

- Prefer expanding PU foam sealant (not reacted on site) and acrylics over polyurethane, silicone, or polyether.

- Avoid orthophthalates (commonly referred to as “phthalates”).

- Prefer low-VOC acrylic-based sealants with reference to SCAQMD Rule 1168. Options with ≤ 25 grams per liter (g/L) VOCs are available for many applications.

- Reduce the use of lower-ranked sealant types.

The detailed Product Guidance for sealants is available on the HBN website.

Putting Theory Into Practice

Whether you are working in new construction or retrofits and upgrades, adopting this insulation and air sealing guidance as part of energy efficiency programs can make a big impact by reducing the amount of hazardous chemicals introduced into buildings. Because chemical exposures tend to disproportionately affect low-income communities, it is imperative that these measures be implemented in multifamily affordable housing. Doing so can help prevent further impact on these communities.

For this reason, in 2020 we surveyed 18 low-income multifamily housing energy efficiency programs in five states to identify barriers and opportunities to incorporating this healthier materials guidance. The results can be reviewed in detail in a report published earlier this year. Barriers to the inclusion of insulation and air sealing as part of low income, multifamily retrofits included limited access to units, programs not allowing HVAC and/or building enclosure insulation and air sealing measures, and programs not supporting the implementation of these measures. Nevertheless, many opportunities exist to better support the use of healthier insulation and air sealing materials in energy efficiency programs. One big opportunity is for all actors within retrofit programs to communicate about what materials are being used to meet the requirements of energy efficiency upgrades. This type of communication is key because it can help foster conversations about implementing healthier material considerations into energy efficiency programs.

In addition, there are some simple steps that you can take to ensure that healthier materials are used in your projects.

- Contractors: Consider selecting safer materials using HBN’s insulation and sealants Product Guidance. These products will help ensure that you are reducing sources of hazardous chemicals from the spaces you are building or upgrading and protect you and your workers.

- Energy Auditors: Identify where materials ranked higher on the Product Guidance can be used to meet energy efficiency goals.

- Energy Efficiency Program Managers/ Implementers: Make sure that you have a communications pipeline with contractors to understand what materials are being used to meet the requirements of energy efficiency retrofits and upgrades. Consider building incentives for using healthier materials into energy efficiency programs.

Conclusion

As we work to lower energy bills and curb greenhouse gas emissions, it is also possible to use materials that improve indoor environmental quality and that are better for public health and the environment. It is important to ensure that these benefits are distributed equitably. Some of the healthiest materials described in this article are also the most affordable. Selecting these materials can be an important step in creating healthier spaces anywhere, including affordable multifamily housing.

Earn CEUs

Earning CEUs on the BPA Journal is a member-exclusive benefit. Please log in to complete the quiz and earn them or join as a member today.