Aug 18, 2023

Field Quality Control – An Outdated Idea or a Necessary Process?

There is no substitute for verifying projects in person.

By: Charley Cormany

As a program administrator for the Sacramento Municipal Utility District (SMUD), Efficiency First currently manages several residential rebate programs. One of our most essential services is field quality control inspections (FQCs).

Sending an individual to review projects after completion is expensive, but we believe it’s worth every penny. Many in the industry are exploring other means to gather information about their projects without physically visiting them. I understand the intent and why this might seem appealing, but I caution anyone going down this path. There is no substitute for verifying projects in person.

As you can imagine, performing FQCs on every project is impossible – the cost would be enormous. Last year we processed over 3,500 projects. That would require many person-hours and more money than we have in our entire budget. Instead, we verify about five percent of all projects. We try to verify more projects from new contractors entering the program. We also may inspect projects based on a complaint from a customer. If we see a contractor repeating the same mistakes, we can increase their verification rate too. The goal of these verifications is both to ensure that customers get what they pay for and that the utility paying for the rebates is providing the intended benefit.

To participate in a SMUD program, contractors must agree to field quality inspections. Knowing they could be inspected gives contractors a strong incentive to do their best work. If issues are found, they must return to the project and make the corrections at no cost to the homeowner. As you can imagine, going back to projects (callbacks) is a contractor’s least favorite task. Correcting problems from a previous job is costly and limits your ability to take on new projects.

Health and safety issues are the most important thing we look for in a field quality control inspection. Next, we want to make sure the projects meet our Program Requirements. We then assess the overall quality of the work, and finally, we look for missed opportunities. The first two factors are critical, and the last two are subjective but provide helpful information.

Not all programs have the same level of investment in field quality control inspections. Some rely on feedback from building inspectors. It makes sense on paper, but I caution you that it is not a great idea in the real world.

For one thing, building departments these days are often woefully understaffed. Before 2008 our small town had three full-time building inspectors to inspect and approve construction projects to ensure they comply with local building codes. During the great recession, construction ground to a screeching halt, and the building department laid off two of the three inspectors.

Building departments have been slow to replace inspectors as the economy turned around, primarily due to cost. Revenues are down, and the pandemic took us all for a ride. The net effect today is that most building departments are understaffed and struggling to provide minimum service.

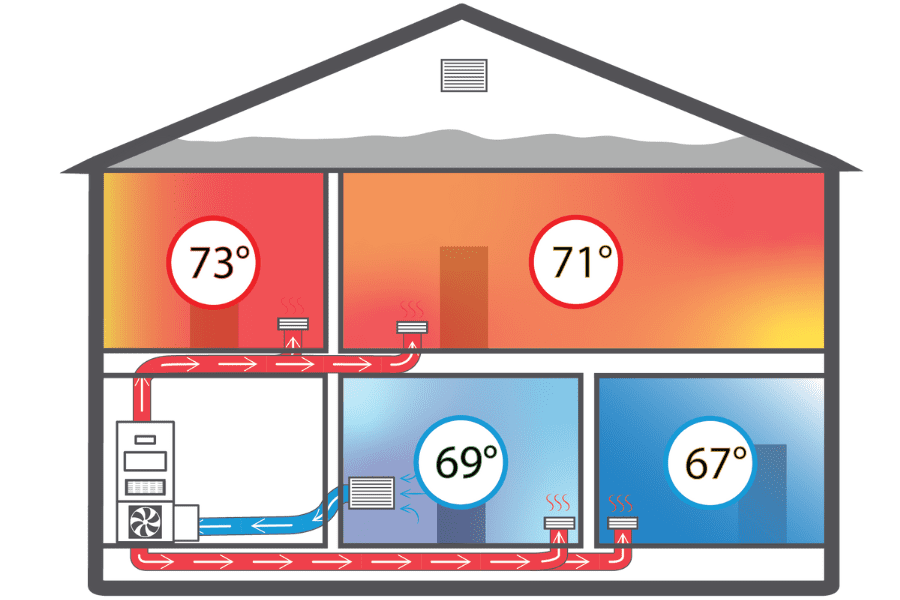

Because of this, building officials are overburdened and under-supported. When an inspector shows up for an inspection, they are typically in a hurry. They have to pick and choose what aspect of the project is most important. Hopefully, they focus on health and safety concerns and consumer protection. The performance of the heating, ventilation, and air conditioning (HVAC) system is a lower priority.

In addition, many building inspectors are former contractors. Most residential contractors know a fair amount about carpentry, a bit about plumbing, a bit about electrical — and not so much HVAC systems.

This is a problem, as most rebate programs are focused on energy efficiency and decarbonization. After sitting for inspections for years, I can assure you that most building officials don’t understand either. They review their checklists, tick the boxes and move on. I don’t blame them; this is how the system has been designed. But building inspectors would not be my first choice if you want accurate HVAC or water heating project data.

What about third-party inspectors?

In California, heating and cooling system replacements trigger a third-party inspection known as a Home Energy Rating System program inspection, or HERS, rating. Before the contractor can call for a building inspection, the HERS rater must test various parts of the heating and cooling system to ensure they are working as per the manufacturer’s design specification. On paper, the HERS system makes a ton of sense. Instead of forcing a building inspector to learn heating and cooling systems, you use an expert to test them and provide the results to the building official during their inspection.

As good as this approach sounds, there are a couple of fundamental flaws. The first is that the HERS testing requirement gets triggered by pulling a permit. It did not take contractors long to figure out they could avoid HERS testing entirely by telling the customers a permit was optional. Even though this isn’t true (permits are legally required for any project in California over $500) less than 10% of residential HVAC replacements are permitted.

The second issue with the HERS process is the independent third-party raters are hired by — get this — the contractor. So now we have a system where the person doing quality control (HERS rater) is paid by the entity they are inspecting. What do you think happens when an honest HERS rater fails many projects for a contractor? In fairness, the California Energy Commission, the party responsible for the HERS rating system, is aware of these issues and is actively working on solutions.

Recently a new approach to rebates has been promoted. Pay for Performance (P4P) programs shift the attention away from what measures qualify for rebates and focus on the outcome. A program aimed at energy savings, for example, bases success solely on meter data, allowing the contractor to choose the best way to meet their metrics. These programs promote cost savings by reducing administrative burdens by not requiring third-party verification. I favor measured savings; actual data is tough to beat. That said, I don’t think these programs will do well if there is no formal process for checking on the actual work completed and the quality of the installations. There is an old saying that comes to mind: “Trust but verify.”

Why am I so skeptical of using third parties, such as building inspectors or HERS raters, as a proxy for field inspections?

We perform field quality control inspections daily. Our team reviews each of our field quality control inspections, which typically happen after a city building inspection and a HERS rater have been on site. Let’s just say a lot slips through the cracks.

The list of issues we find post inspections is extensive. Some of the problems are somewhat trivial, and others are life-threatening. We send contractors back to projects every day to clean up mistakes. I don’t blame the building inspectors, but I hold the HERS raters somewhat accountable, as many stretch the truth to get projects passed so they get paid.

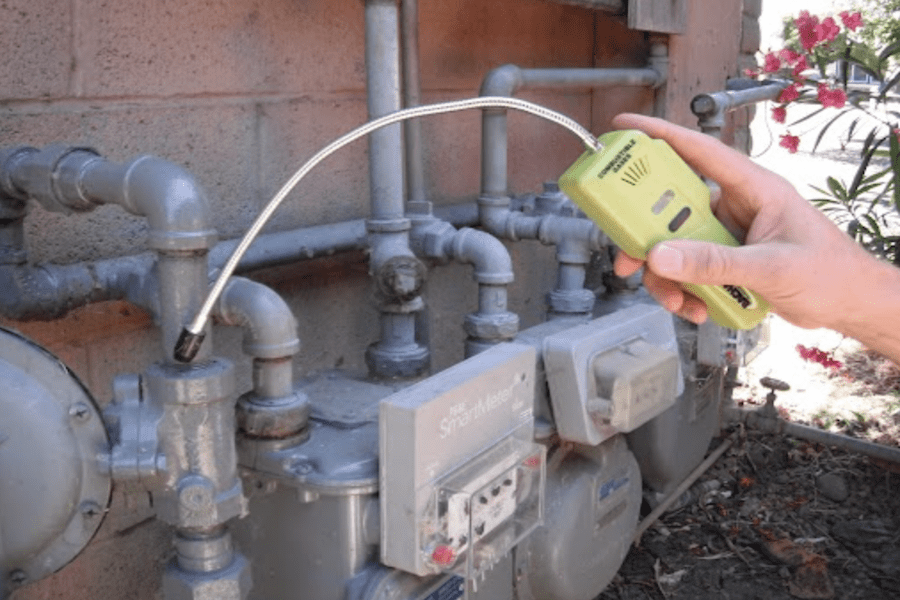

The worst issues are related to health and safety. Perhaps the most frequent health and safety concern we find is natural gas leaks. If it were up to me, every building inspector would carry and use a gas sniffer. Gas sniffers are a small hand-held tool that detects the presence of combustion gases. They are super sensitive and easy to use.

In the SMUD program, our goal is to convert homes from fossil fuels to electricity. The result is that most of our projects include a legacy gas line used by the existing equipment. We require all gas valves to be removed and the gas line capped. Gas lines are not something building officials or HERS raters check regularly.

We find all kinds of issues with legacy gas lines. The worst case is when the contractor disconnects the flex line to the equipment and leaves the rest of the gas infrastructure in place. We had one project where the contractor used duct tape to seal the end of the gas line and prevent the gas valve from being accidentally opened. Guess what happens to duct tape in a hot attic or, in this example, a garage? It does not take long for it to dry out and fall off. In this case, the gas line was sticking out next to a washing machine in the garage. The valve was intact and uncapped. All it would take is a bump with your leg or to get snagged on a piece of laundry, and that gas line would fill the garage with unburned natural gas. That’s a bomb waiting to happen. And remember, this project passed a HERS test and a building inspection.

Another case was a roof-mounted package unit that was replaced with an electric roof-mounted heat pump unit. The contractor felt compelled to add heat strips to the heat pump (which we don’t need in California – that’s another conversation). The combined draw was 80 amps. That’s a ton of juice for a building whose electrical service panel was rated at 100 amps for the entire house. Even worse was that the particular brand of panel was known to fail to trip under load. (If you have a Zinzco or Federal Pacific service panel, you might want to consider replacing it. They are everywhere in California and cause fires. Ask me how I know.) This project passed inspection and did not require a HERS test, as they did not replace the ducts.

This might all seem pretty dark and hopeless, which it can be, especially if you rely on the building department or HERS rater to validate the results of your projects.

There can be a good side to all of this though. We use the results of our corrective actions as a metric for training the contractors in the program. When we see a pattern of failed field quality control inspections, we contact the contractor and require them to attend a mentoring session with one of our senior field quality control inspectors. The mentoring session does not focus on the mistake. Instead, we help them understand the issue and show them ways to improve their process.

Training the crew or HERS rater in the field has produced significant improvements. Once they know you are interested in their success, they are more than willing to learn and appreciate our time and effort in their process. Mentoring is expensive, but it has been the most effective form of education we have found to date. Educating the right people, those actually doing the work, is critical.

Field inspections combined with in-the-field mentoring are the best way to improve quality. If you are committed to quality, you must see the projects yourself. It is really that simple.

This article originally appeared in the Efficiency First California blog and is republished with permission.