May 6, 2024

Industry Trends to Watch in 2024

The future of clean energy will be shaped by the continued value of energy efficiency, the importance of decarbonization efforts via electrification, and the growing prevalence of heat pumps.

By: Charley Cormany

Efficiency, Electrification, and Decarbonization: Key Trends and Innovations in 2024

If you work in the energy industry, you’ve probably noticed that you could spend the first three months of the year bouncing around from conference to conference. Pick a subject, pick a week, pick a state; there are tons of choices. Just as in previous years, I’ve already been to several.

These days, I attend conferences to keep an eye on new trends and technologies and then share that information with contractors and others in the industry. Hopefully, folks like you will benefit from this information and use it to improve your businesses.

Here are a few of the trends I observed this year.

Improved Energy Audits

A growing number of home performance businesses are looking for ways to do energy audits without being on-site. Obviously, this would save a ton of energy and effort. Some folks have the homeowner serve as the contractor’s “eyes” in the field using their phone. The homeowner walks around and live streams video while the contractor watches from the office. The contractor can ask the homeowner to get a different look at something or a more detailed shot, as the images are being shared in real-time.

Another new technology I’ve seen is using a digital phone to create a detailed room map. The image maps can later be used to fill out the basic information required to create an energy model. Typically, this information is referred to as a “takeoff .” Getting accurate in the field is a time-consuming process. The potential of using your smartphone combined with intelligent technology to simplify and speed up the process of doing a takeoff is very appealing. There is more than one company offering these smartphone-building rendering software solutions. If you are a contractor, you might want to consider using one.

The Grid Benefits of Energy Efficiency Upgrades

Policymakers around the country are counting on the savings from energy efficiency as a part of their emission reduction and clean energy goals. For years, we have been promoting the additional benefits of energy efficiency upgrades, such as indoor air quality, comfort, health, durability, and so on.

Today, many people are concentrating on the benefits of energy efficiency improvements related to the electrical distribution grid.

For example, if you are in a neighborhood with many older homes, you may be able to electrify the entire neighborhood without upgrading grid infrastructure. How? The answer is straightforward: use efficiency upgrades to reduce energy use first. Several recent studies have demonstrated that efficiency can be a viable pathway to electrification with less infrastructure investment. The utilities see the benefits, and perhaps you should, too.

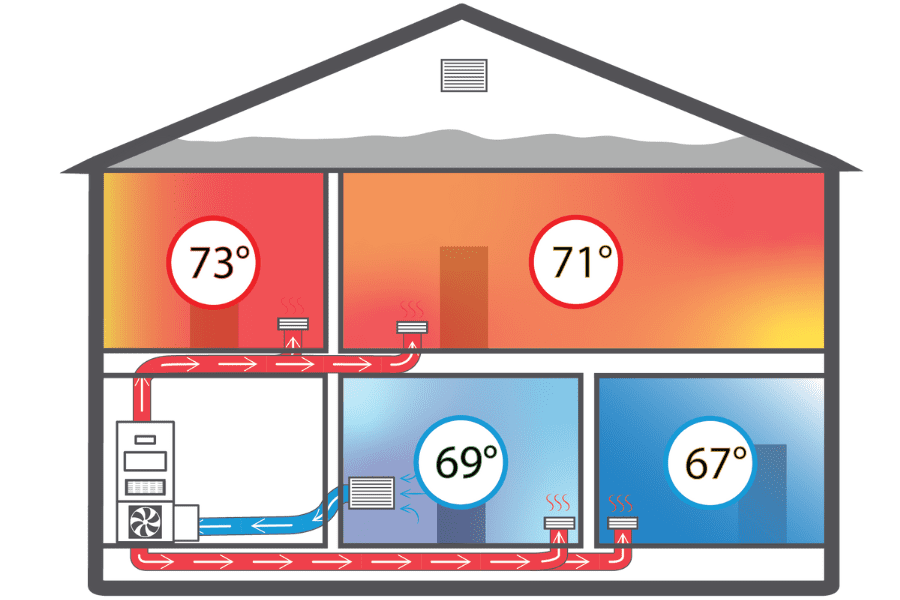

Here’s another example. To avoid overloading the grid during periods of high demand, utilities are expanding their use of demand response (DR). A simple example of DR is having an electrical box on your air conditioner, allowing your utility to turn the unit off remotely during peak demand periods. If you live in an old, crappy house, it might get hot very quickly if the utility turns the air-conditioning off, even for a brief period. If you live in a tight, well-insulated building, you might be able to “glide” for hours before even noticing a temperature change. By making it easier to maintain a consistent temperature in a building, efficiency makes demand response a more viable solution for utilities and homeowners.

There are a whole host of vendors selling DR software solutions. Many of these technologies interact directly with heating and cooling controls. This year, smart thermostats and sophisticated building management systems for commercial applications were everywhere. Thanks to advanced digital controls, “smart buildings” are becoming a reality.

Doing More with Less

One of the challenges of decarbonization and building electrification is electrical service panel capacity. Many in the industry believe that to electrify a home or building, you must upgrade the electrical panel first, which is sometimes the case.

New studies, however, show you can do most electrification projects without upgrading the existing service panel. It all boils down to using your existing capacity efficiently. You might need to take a slightly more educated approach, such as purchasing a few new energy-efficient appliances, an energy monitoring system, or a load-sharing device.

Want to take it a step further? Smart electrical service panels monitor and shift electrical loads to maximize performance — without any input from the occupants. Smart panels make a ton of sense once you include solar production, storage, and electric vehicles. The panel can maximize efficiency by sending excess solar output to a battery or your electric vehicle before sending it back to the grid. This takes advantage of lower utility rates at off-peak hours by storing electricity when it’s less expensive and using it at peak times when rates increase. I suspect we will see far more intelligent building control systems for commercial and residential applications. Every show I attended had multiple vendors offering new Building Energy Management (BEM) systems.

Are Heat Pumps Viable in Commercial Applications?

I attended a Heating, Ventilation, and Air-Conditioning (HVAC) conference to see if heat pumps are entering the commercial sector. Overall, I was disappointed to see so many commercial systems still relying on fossil fuels. Commercial heat pumps are getting some attention but are not nearly the poster child for the future, as they are with residential applications.

One exception is air-to-water units. Most residential heat pumps today transfer heat from the air to a refrigerant. The refrigerant then flows to the end use, be it a wall-mounted air handler or a more traditional air handler with ducts. Either way, the energy is moved from hot to cold or the opposite via refrigerants.

An air-to-water heat pump extracts heat from the air and moves it to water. This opens the door to a wide range of applications. For example, you could use a single heat pump for both space and water heating. For years, fossil-fuel-heated boilers have dominated combined heat and water. Replacing boilers with heat pumps could be a game changer.

Another application of an air-to-water heat pump would be for radiant heat. Warm floors are preferred in many high-end homes and other applications. Using a heat pump to provide warm water instead of a boiler is a great solution. It’s super-efficient, uses electricity that can be generated with zero emissions, and has no site-produced emissions.

The next step for commercial applications will be air-to-steam heat pumps. This technology is getting traction and could soon be mature enough to replace multitudes of gas and fuel oil boilers in commercial applications. New refrigerants are making headway, too, with low global warming potential (GWP) alternatives, which the industry needs for mass adoption.

In summary, the commercial applications of heat pumps are growing. I was disappointed that they were not as prevalent as they have become in the residential market.

Where Are the US Manufacturers?

At one of the conferences, I vowed to visit every booth, which was quite a task as there were over 1,800 vendors. I took a lot of notes over two days and eight miles of walking. One of the main things I noticed was that we, as a country, are falling behind in the heat pump manufacturing space.

The majority of residential heat pumps are manufactured in other countries. Japan started as the dominant force, but today, China has emerged as the primary residential heat pump technology supplier. Many products sold in the United States are “white-labeled” versions of Chinese products, meaning the US manufacturers buy their products from Chinese manufacturers and put their own labels on them. The rebranded units are marketed based on the legacy reputation of the US manufacturer. This is not a new practice or specific to the industry — white labeling has been going on for years in all sectors of the economy.

The lack of US manufacturers is a concern to me. We are putting a great deal of faith in heat pumps as a viable solution to meet our state and federal greenhouse gas reduction goals. Relying on sometimes unstable trading partners to support this effort feels risky. I am aware that the US manufacturers are working on developing their products. Hopefully, we can play more than a supporting role in the clean energy sector.

Sustainable Is on Everything These Days

It was amazing how many manufacturers and vendors promoted the sustainability of their products or services. Greenwashing is nothing new, but it can sometimes be a bit annoying. How sustainable is a 25-ton gas package unit? (HVAC system) Do they consider it sustainable because it is more efficient than its predecessor? The label was everywhere, and I don’t think many of the products were truly sustainable, in my opinion.

A Small Sampling of Things I Felt Were Relevant

I have touched on a few new topics and technologies here, but there is way more to the conversation. If you read something above and would like more details, contact me. I would be happy to expand on any of the ideas listed above.

The industry is changing rapidly, but there are three consistent themes: The continued value of energy efficiency, the importance of decarbonization efforts via electrification, and the growing prevalence of heat pumps. These things combined will shape the future of clean energy.

Are you ready to take advantage of this opportunity? Change is coming, and with change comes opportunity. We at Efficiency First California are doing our best to keep you informed so you can succeed. We recognize that the bulk of this transition relies on contractors. Your success is our goal, and hopefully, you can use some of this information to position your business to become a leader in the clean energy transition.

This article was originally published in the Efficiency First CA blog and is republished with permission.