Jun 7, 2023

What if Houses Came with Manuals?

A guide to the “House As A System” approach to understanding comfort, IAQ, durability, and energy consumption issues caused by building air leakage and HVAC driven pressure imbalances in single-family homes.

By: Sam Myers & Genry Garcia

How does a house operate? It seems like a silly question. Houses are stationary objects, right? What else is there to know? This may seem like the case at first glance; however, the physical activities of a home are always in motion and are constantly changing. Air is always infiltrating and exfiltrating at rates that change with the weather and when mechanical systems are powered on and off. This impacts our level of comfort, the quality of the air we breathe, and the amount of energy we consume, and it can even affect the lifespan of certain structural parts of the house.

Every mechanical system we install in a home comes with an operating manual. But what about the rest of the house? Have you ever seen a builder provide an operating or owner’s manual for the house itself? For such a large investment, one would think there would be a guide to show how each part of the home should operate, how to troubleshoot, and how each component should be replaced at the end of its life, or at least adjusted should something else change. Unfortunately, they don’t. And they likely never will. Homes are complex structures without a complete manual for total operation. Fortunately, the physical behaviors of every house abide by the same laws, and these laws allow behaviors to change throughout the year and across different climate zones. The goal of this article is to show how a house works and where the source of many problems stems from regarding comfort, energy, durability, and indoor air quality (IAQ).

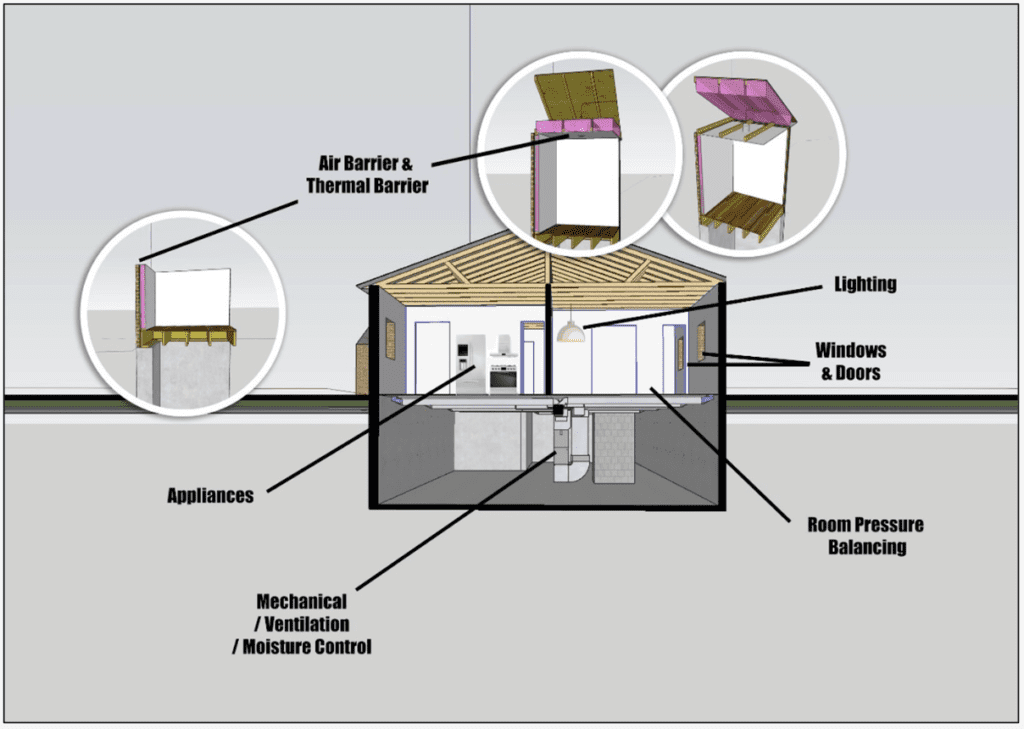

Stick-built homes are the most common single-family structures in the US. They have a long-standing history that goes back prior to the Revolutionary War. In the early days, these homes served as large boxes that kept us dry and safe. As new inventions, materials, and processes advanced with technology, our homes have become more complex, with many components that must work together to be effective and efficient, similar to the human body (we’ll return to this later). Therefore, if we change one part of the home, it can impact another. Aside from shelter and safety, the primary purpose of a modern home is to provide comfort and IAQ within a reasonable operating cost. There are two main parts of the home that make optimum comfort and IAQ possible: the building envelope and the mechanical equipment. It is imperative these two systems work together to avoid issues such as high humidity, poor air quality, uncomfortable rooms, mold, rot, dust, and warped wood floors.

The Mechanical System

Let’s cover the obvious first. The HVAC system and its many components have the important job of delivering thermal comfort throughout the year. However, systems must be sized and designed properly to deliver peak performance. To determine the appropriate size, an ACCA Manual J load calculation should be completed. And to improve Manual J’s accuracy, a blower door test should be done to determine the amount of outdoor air infiltration (more on that later). Unfortunately, a large percentage of new systems are installed without employing this process. Equipment sizing is typically guessed based solely on the square footage of the home, usually 500 sq. ft. per ton. This method can grossly oversize the system and cause it to short cycle, which means the thermostat set point is reached too quickly. This can shorten the lifespan of the equipment and prevent the HVAC system from dehumidifying the home due to shorter run times.

One key component that is often omitted in American homes in the “V” in HVAC, which stands for ventilation. We’ll later discuss how ventilation is a way the mechanical system can work with the building envelope. Having properly designed ventilation is critical to providing cleaner indoor air. When we neglect to bring in outdoor air, we cycle the same air through the house over and over. Eventually, that air collects volatile organic compounds (VOCs) that off-gas from building materials and appliances along with other pollutants that we breathe. This makes good filtration another key component for better IAQ. Adequate ventilation and filtration work well together to provide a healthier living space.

There are many options available for residential ventilation. Energy and heat recovery ventilators (ERVs and HRVs) provide balanced ventilation by bringing in outside air and exhausting stale inside air at the same rate. Air cyclers are another option. These involve a duct connected to the return side of the system from the outside of the home. There is a motorized damper on the duct that opens on a set schedule to allow the air handler to pull in filtered outside air. There are now ventilation control options available that run the ventilation based on readings provided by an IAQ monitor. Ventilating dehumidifiers are another option that can provide dehumidification and filtered outside air at the same time for homes in humid climates. Air cyclers and ventilating dehumidifiers apply a slight positive pressure on the building envelope, which can sometimes keep moisture and other contaminants from infiltrating as easily.

The Building Envelope

The building envelope serves as the container for the product HVAC contractors provides to their clients. This outer skin of the building holds in all the conditioned air that keeps us comfortable. So, wouldn’t we want to know if the building envelope is doing its job? Another way of looking at it is this: Let’s say our job is to keep water in a bucket. Wouldn’t we first want to know if that bucket has any cracks or holes in it? As conditioned air escapes a leaky building envelope, unwanted outdoor air is also infiltrating inside that is cold in the winter and warm in the summer. This causes certain rooms to be of an undesirable temperature, making it difficult to take full control of comfort inside the home. The leakier the envelope, the less control we have over maintaining an enjoyable living space.

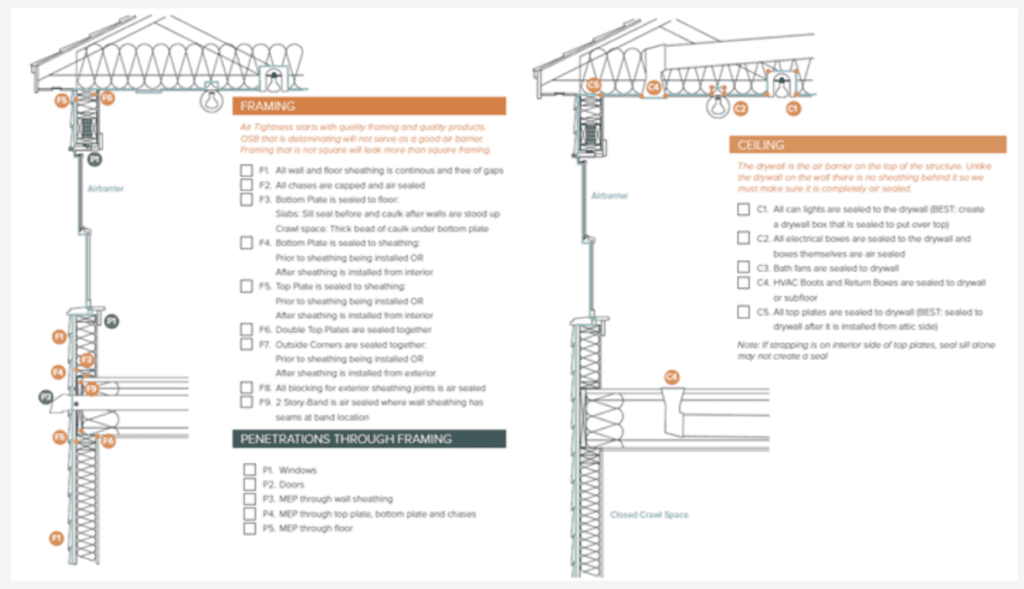

A tight building envelope is critical to delivering optimum comfort and IAQ. The myth that “a house needs to breathe” is a misconception our industry has been battling for decades. Before the building industry began its focus on airtight envelopes, we relied on air leakage to serve as ventilation. As we mentioned earlier, it is true that we need to bring in air from the outside to maintain a healthy living environment. However, relying on cracks and gaps in the envelope is not an ideal source of “fresh” air. This is a practice from an earlier time before we as an industry knew about measuring air tightness and its impact on comfort, energy, IAQ, and durability. We now have sophisticated tools and software to assess building enclosures and duct systems quickly and effectively. We also have the ability and design mechanical ventilation systems that provide cleaner air without compromising the envelope’s integrity. This is one way the HVAC system and building envelope work together.

There is a big difference between infiltration and ventilation. Ventilation is when outside air is carefully quantified, filtered, and often pre-conditioned before it enters the living space. Infiltration is when the unplanned air from the outdoors gets into your home, carrying everything from heat and humidity on warm summer days to contaminants from attics, crawl spaces, basements, and wall cavities. If the house is leaky enough, various types of pests can make their way in and leave undesirable substances that can eventually become airborne and enter the living space with the infiltrating air. As you can imagine, this is a huge tax on IAQ. Pollen and other air pollutants can travel inside leakage pathways from the outdoors as well.

Treat the Source, Not the Symptom: The Physician’s Approach

Earlier, we mentioned how various components of the building envelope and HVAC system can have an impact on each other similar to the functionality the human body. For example, if you take one medication for a symptom, it could have a side effect on another part of the body. Houses and HVAC systems work in a similar fashion. It is important for us as diagnosticians to understand how each part of the home can impact another.

When we visit the doctor for a symptom we’re having, a series of questions are asked along with some testing to identify the source of our discomfort. Technicians can follow a similar process by asking themselves a few questions: What needs to change to make the client happy? Could this be an equipment issue? Duct issue? Envelope issue? A mixture? What tests make sense to use to find the source of discomfort?

Building Envelope Diagnostics

To fully grasp if and/or how the building envelope is contributing to the comfort and IAQ symptoms, there are three things we need to clarify. We’ll need to:

Determine the amount of leakage in the building envelope. Does it appear to leak more than it should?

Determine how the leakage is distributed throughout the house. Are some areas more severe than others? Do these areas align with customer complaints?

Determine how the home’s mechanical systems interact with the envelope leakage. Do room pressures change when the HVAC is on vs. off? Does the overall house pressure change when the HVAC system(s) or exhaust fans are running?

These steps are usually conducted in this order. In this section, we’ll discuss a variety of methods that can be used to locate issues in the building envelope. And to reference our comparison to medical professionals, sometimes it’s best to use more than one method to see if they agree with each other. This can increase confidence in our findings as we work to narrow down the source of the occupant’s discomfort.

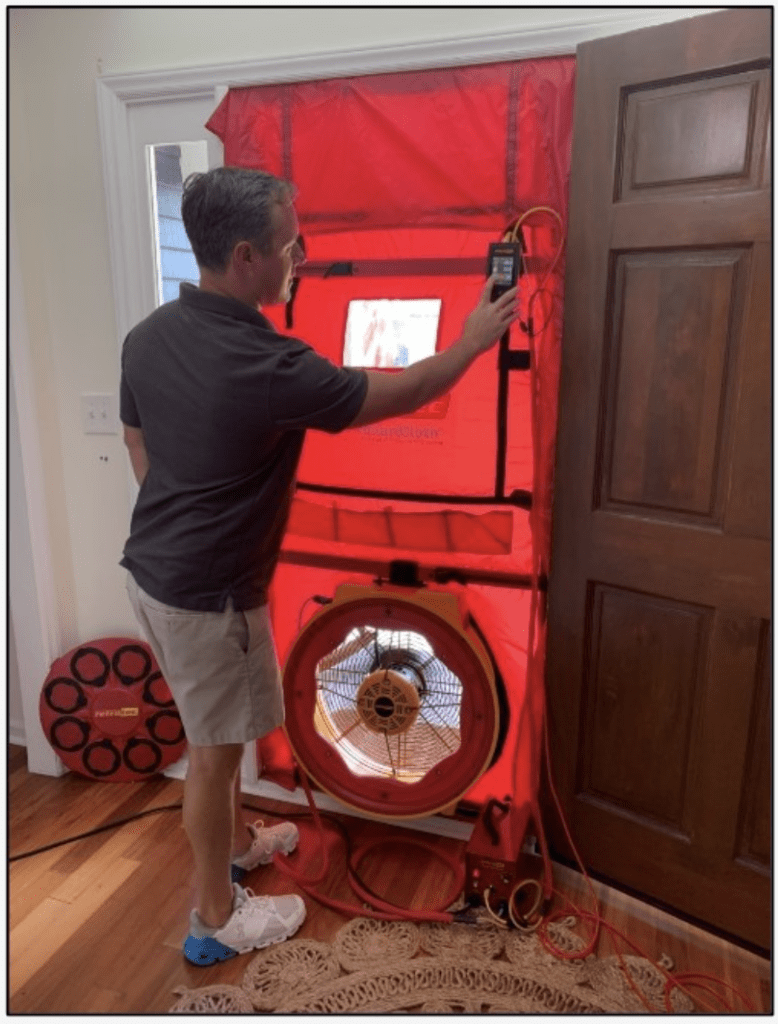

To begin our process, we need to determine how much the building envelope is leaking. This is done by using a blower door: the single most important tool when it comes to home performance analysis. Imagine being an orthopedist without an X-ray machine…that’s how important a blower door is here.

Envelope testing and diagnostic procedures are very involved subjects, and there are many free resources available to learn all about these topics in great detail. To quickly summarize, we use the blower door to pressurize or de-pressurize the home’s envelope to a known and controlled pressure with respect to (WRT) to outdoors, normally at +/-50 Pascals. This allows for a stable investigative environment, as this induced pressure is enough to negate any stack-effect and wind-induced pressures.

With some additional tools, the blower door can also show us where the leaks are located. There are multiple ways to do this, and the best method for a particular house on a particular day may depend on the weather conditions and/or construction type. This detailed Residential Pressure and Air leakage guide is a great reference to dig more into the subject.

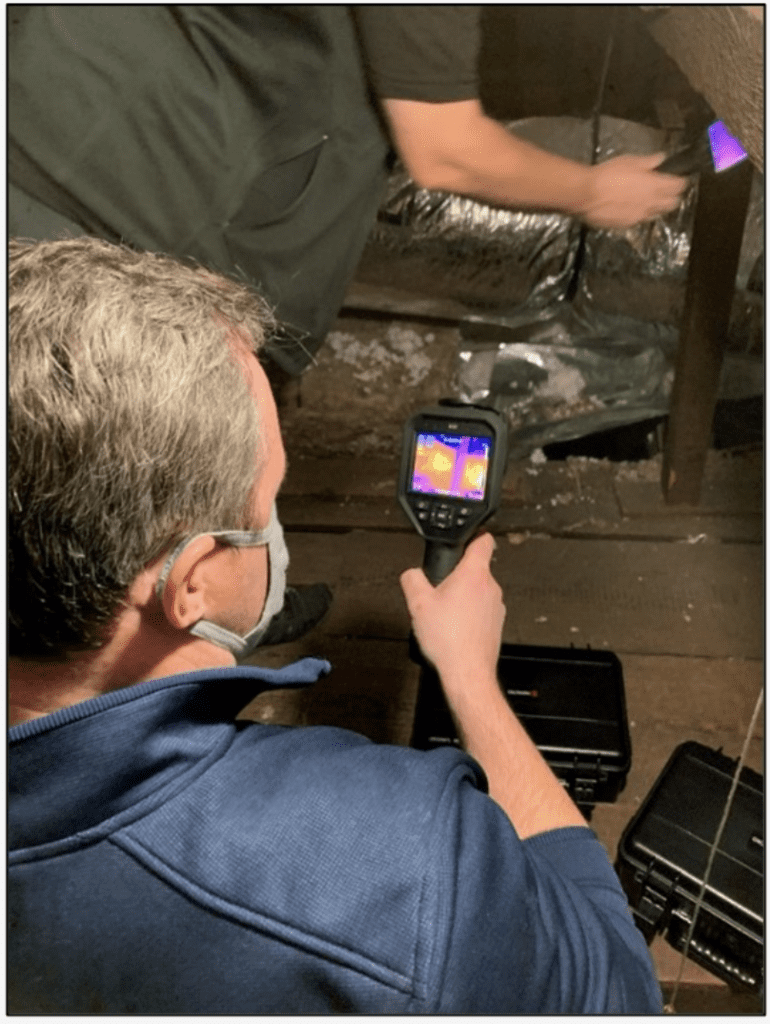

Thermal Imaging & Smoke Tracers

Once we’ve measured the total air leakage through the envelope, we’ll need to get an idea of how the leakage is distributed throughout the house. In many cases, the blower door test can appear acceptable, but we may later discover most of the leakage is concentrated in one area. Air leaks can be tricky to pin down sometimes, mainly because we can’t see what is happening with the naked eye. Any way we can make leaks visible helps us to quickly locate the sources of discomfort. A good thermal imaging camera can be one of the best ways to do this, as it allows us to photograph leaks that we couldn’t see otherwise. After all, seeing is believing.

Thermal imaging can quickly reveal heat flow patterns through wall cavities and/or envelope leaks. However, there needs to be enough temperature differential between indoors and outdoors for a leak to be easily visible. Generally, ten or more degrees of temperature difference will do.

Smoke tracers or puffers are another great visual tool. It is not actual smoke. Instead, it is a fog produced from a glycol solution like what you see in theatrical fog machines. As we pressurize the building with the blower door fan, the fog moves with the air currents generated by the fan and leads us to the problematic areas.

Zonal Pressure Diagnostics (ZPD)

ZPD is a great way to quickly assess how leakage is distributed throughout the house by determining how leaky the ceiling, floor, or attached garage is. It has, unfortunately, over years of poor practice, de-formed into a process to “estimate” interior room leakage. While this practice surely aids the sales part of home performance testing, it can hold very little technical legitimacy. However, when used properly, ZPD can give us a great deal of information about leakage distribution across the envelope. The high-resolution manometer that comes with the blower door system can be used to run these types of tests.

This series explains how ZPD works in more detail.

The HVAC System’s Effect on the Envelope

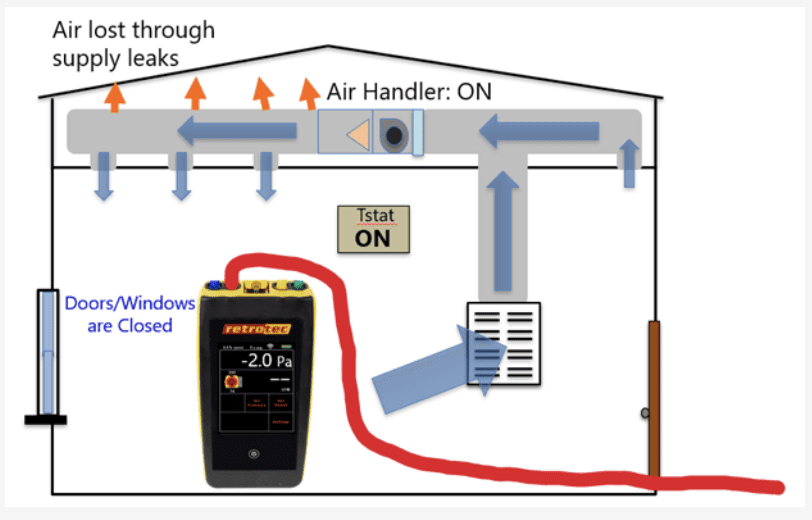

A Negative House is Bad

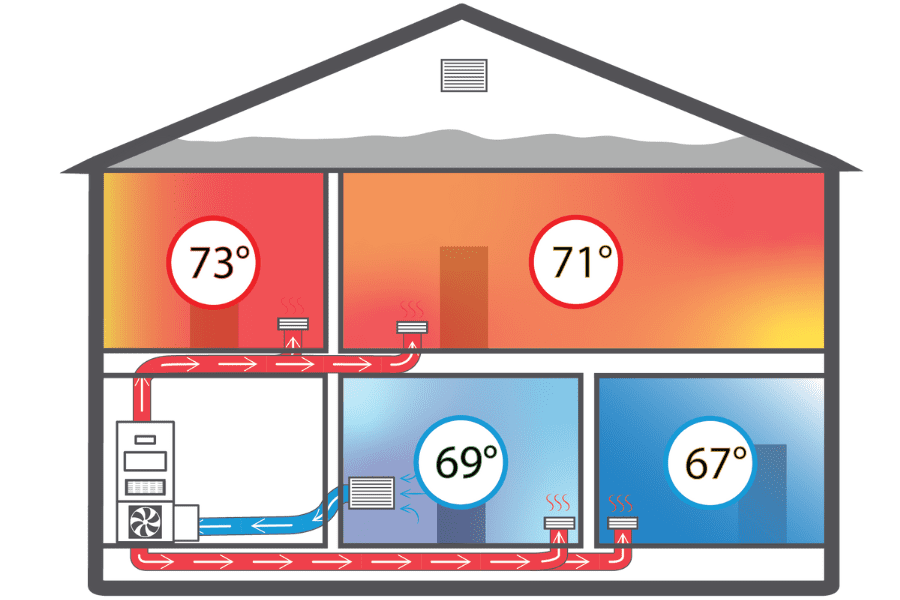

In many parts of the US, duct systems are often located outside of the building envelope, whether fully or partially. This location could be a vented attic, vented crawlspace, unconditioned basement, or some other vented outdoor enclosure. For duct systems located outside of the building envelope, ducts that leak more on the supply side than the return will drive the home’s pressure down. This makes the house negative WRT on the outside of the home. As the HVAC system runs, it pulls air from inside of the house and dumps it outside of the conditioned space through leaks in the supply ducts. This allows the return to pull more air from the house than the supply side distributes back to the house, thus drawing the house negative.

For example, if the supply is leaking 100 CFM more than the return, this amount of conditioned air is lost every minute the HVAC system runs. At the same time, unwanted and untreated infiltration air from outdoors is being pulled inside through envelope leakage. This is referred to as HVAC-driven depressurization, meaning it only occurs when the HVAC s. Some parts of the year will be more extreme than others. Depending on the climate and/or time of year, this outdoor air can be very humid or very dry. Therefore, a variety of IAQ, comfort, durability, and energy consumption issues can stem from this specific issue.

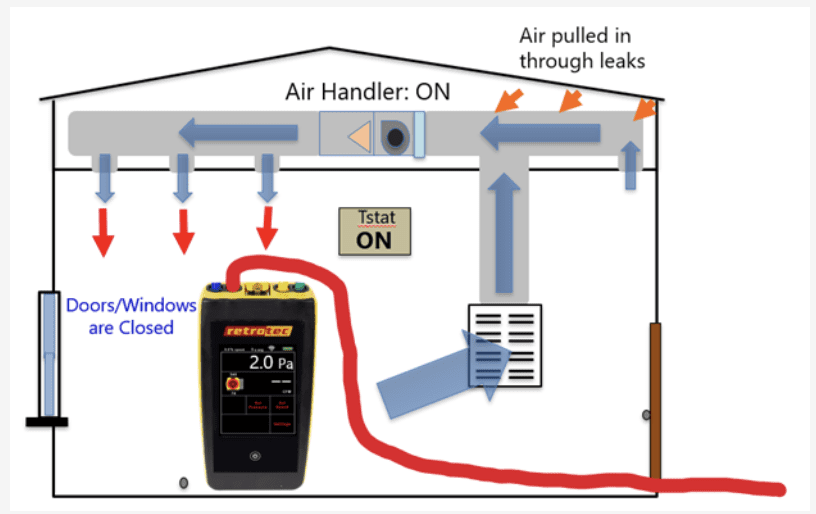

A Positive House is Also Bad

Sometimes the opposite can happen where the return side has most of the duct leakage. This causes the house to be positive WRT outside. If a leaky return duct is running through an unconditioned space, it will pull air from outside the envelope and deliver it to the living space. This issue is exacerbated when air filters mounted on return grilles get dirty since more air is forced through the duct leaks. In some cases, comfort issues are alleviated when air filters are replaced with less restrictive types.

When it comes to IAQ, there is no positive take away from a positively pressurized home through return duct leakage. Where is this air coming from, the attic? The crawlspace? Depending on the climate zone, both locations have the potential to have high humidity, mold, and dust. IAQ, humidity control, and comfort in general are greatly affected by this condition.

So, if the ducts are tight, we have no worries. Right?

Not quite. There are other interacting nuances in the envelope/HVAC relationship that will impact house pressurization, and by default, indoor comfort.

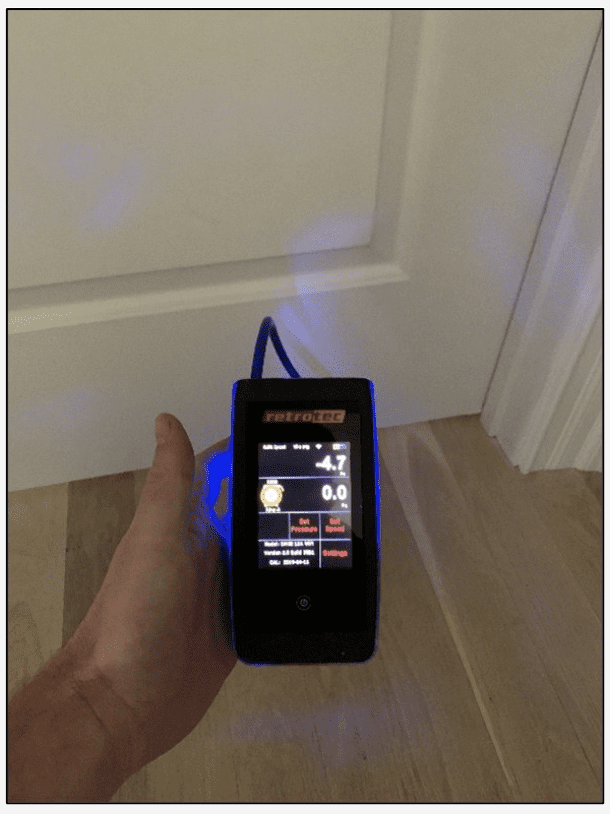

For every room that can be isolated by a door and has a supply air path (e.g., a bedroom), there must be an adequate, equivalent return air path. With the door closed, every CFM of supply air provided to a room should be provided with a path back to the HVAC system. This pathway could be an active return duct, or a passive return air path such as a transfer grille, jumper duct, Tamarack door vent, etc. When the room pressure is equal to that of the main body of the house while the HVAC system is running, it is considered “pressure balanced”. This pressure balancing test should be done with a high-resolution manometer, such as the one that comes with a blower door or duct tester kit. The pressures we’re measuring will be in units of Pascals, so the typical HVAC manometer will not suffice. High-resolution manometers are accurate within a small fraction of a Pascal.

Measuring the pressure of each room can be done alongside the airflow measurements for each supply and return. These airflow measurements are typically done with a flow hood. The correct flow for each supply and return is generated by conducting a room-by-room load calculation. The system installed should be entered into the software to provide realistic flow targets. Each supply and return duct should have an adjustable damper to balance the room. Using the high-resolution manometer and flow hood together is the best way to dial this in. This goes back to the physician’s approach to doing things: having multiple tests agreeing with each other builds our confidence as we identify the source of comfort issues. We typically want flows to be within 10% of the target. By the way, the most accurate flow hoods use their own calibrated fan and high-resolution manometer to take readings.

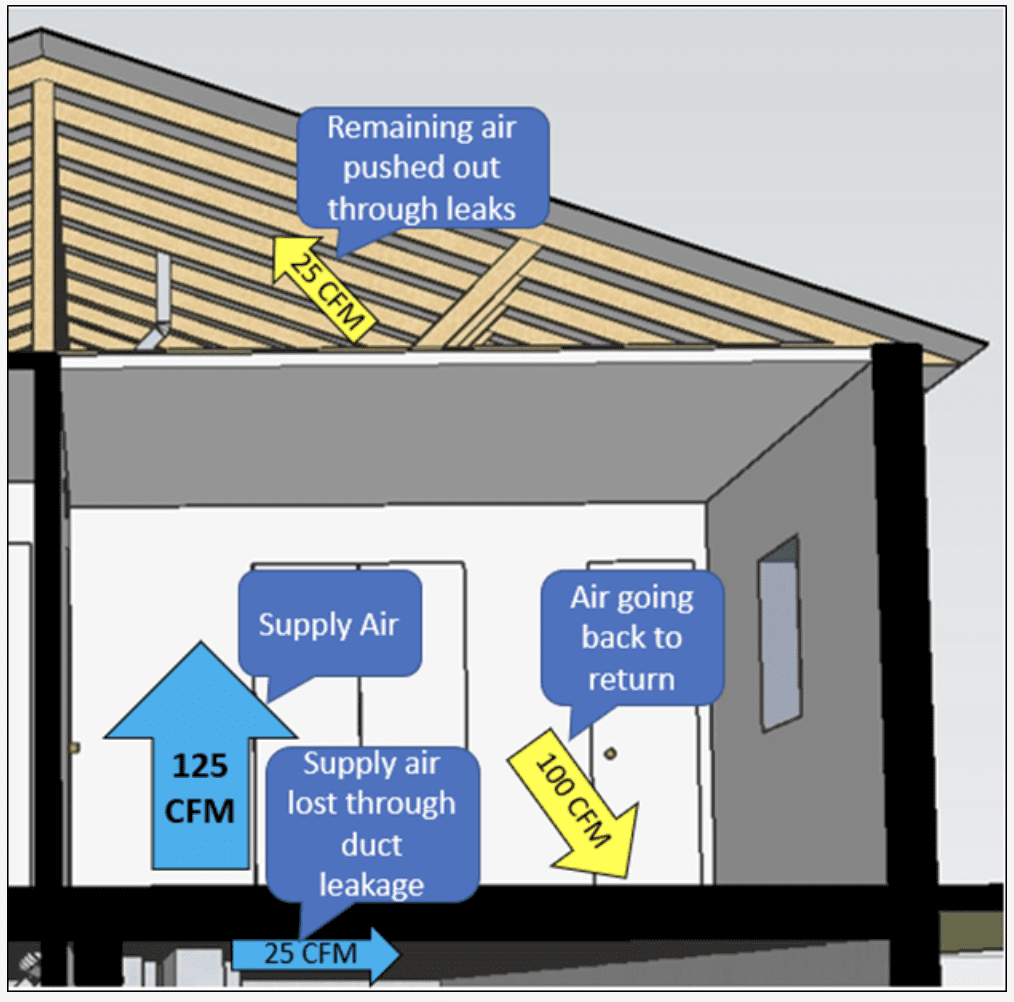

If a room has enough supply air but an insufficient return air path back to the equipment, the pressure profile in the home can become erratic. Using a room-by-room load calc, let’s say we have determined a given bedroom needs 150 CFM of conditioned air. We’ll also say the supply duct layout is adequate to provide that amount of air. But as we see in many scenarios, the return air path only allows 100 of that 150 CFM to get back to the blower. This happens when measures aren’t taken to ensure the room will be balanced. This is a common issue in many homes, as is the lack of verification after systems are installed. If the bedroom door is usually open, who cares? But what happens when the door is closed? In a room with this type of insufficient return path, the room is pressurized to 5-10 Pascals (sometimes a lot more) with the door closed. In this scenario, a loss of at least 10-20% of supply airflow can be expected.

In our hypothetical bedroom with the bedroom door open, we have 150 CFM of supply flow. But once the door is closed, the supply flow can drop to 125 CFM, and only 100 CFM make it back to the blower. This leaves 25 CFM that is pushed out through duct leaks, so it never makes it to the room. Again, the other 25 CFM are pushed out through envelope leaks. This amount may not seem like a big deal, but again, this is only one room. If we have a 4-bedroom house with each room behaving the same way, that’s 100 CFM of air lost to the outdoors every minute the system is running. And remember what happens when we have more supply leakage than we do on the return side? If this is the case, the rest of the house goes negative, thus exacerbating the infiltration paths in other areas of the home.

Another thing to consider is that air leakage can behave differently in a leaky duct system installed outside of the building envelope from the leakage modeled in the load calculation. When a blower door number is entered in a load calculation, it is converted to ACHn (natural air changes). This is the amount of exterior air that will infiltrate under normal operating conditions. It’s great that the software does this for us. However, the HVAC-driven pressures will overpower the natural forces that push and pull against the skin of the house. Therefore, the calculated ACHn value from the blower door number can be a gross underrepresentation of the real infiltration load. This topic can be explored here in more detail. Understanding envelope leakage alone using a blower door is a large step forward. But if significant duct leakage is suspected, it is important to measure its impact and make recommendations for remediation.

When HVAC technicians neglect to measure, locate, and quantify the effects of envelope leakage in a home, frustration can arise in both the technician and the client. The source of the comfort complaint goes overlooked, resulting in multiple visits to the home to address the same complaint over and over. With each visit, superheat, subcooling, and static pressure can often be at acceptable levels. It is worth offering a deeper dive into the home to evaluate the building envelope and see how the HVAC system is affecting it.

There May Not Be a Manual, But There Is a Process

The unfortunate truth is there is no physical manual or troubleshooting guide for each individual home for techs to reference when problems arise. But you can use the steps presented in this article to pave a way forward to locate the sources of your client’s discomfort. Once you are confident in your findings, you can develop a plan for remediation. If all else fails in your normal procedures for troubleshooting, make sure you’re not overlooking the envelope. Remember the three things you want to investigate:

Determine the amount of leakage in the building envelope. Does it appear to leak more than it should?

Determine how the leakage is distributed throughout the house. Are some areas more severe than others? Do these areas align with customer complaints?

Determine how the home’s mechanical systems interact with the envelope leakage. Do room pressures change when the HVAC is on vs. off? Does the overall house pressure change when the HVAC system(s) or exhaust fans are running?

Once you begin to apply these practices in your comfort and IAQ consultations, the confidence you have in your diagnostic abilities will continue to grow. So even if the house itself doesn’t have a manual to reference, you’ll have your own to apply in each home you visit.

This article originally appeared in the Retrotec Blog and is republished with permission.