Aug 2, 2024

Indoor Air Quality for the HVAC Technician – Part 1

This article series discusses some common indoor air quality issues, how to measure them, and how to resolve them so customers can enjoy cleaner air.

By: Brynn Cooksey, Sr., CEM, CMS

(This article is reprinted with permission from the Summer 2024 issue of RSES Journal).

According to the Environmental Protection Agency (EPA), we spend about 90% of our time indoors. The EPA has also concluded that the air quality indoors is two to five times worse than outdoors. Poor indoor air quality (IAQ) has been linked to several illnesses, including allergies, headaches, fatigue, asthma and other flu-like symptoms. These issues are prevalent, yet indoor air quality issues often go undiagnosed and unsolved.

Indoor air quality continues to be an extremely important issue, but it is a relatively untapped market for HVAC contractors. Many people suffer from poor indoor air quality, and even though we are not doctors and cannot cure their illnesses, we can improve their indoor air quality. Large retailers report that indoor air quality is a $10 billion industry, and it is still growing. Every year, individuals purchase millions of products, such as dehumidifiers, humidifiers, air cleaners and air purifiers, in an attempt to relieve some IAQ problems.

HVAC technicians and contractors are on the front line regarding indoor air quality. For starters, every cubic foot of air eventually goes through the air-handling unit of the home or building. Additionally, many IAQ products can be connected to the existing HVAC system to help clean the air and remove harmful pollutants. Numerous studies show that inefficient, poorly maintained, and poorly installed HVAC systems initiate or contribute to poor IAQ. In the case that a person has purchased an IAQ product (such as a humidifier or air purifier), it signals to professionals that the customer has a problem and is spending money to try to resolve it. This article discusses some common indoor air quality issues, how to measure them and how to resolve them so customers can enjoy cleaner air.

Typical IAQ Issues

IAQ issues can come from a combination of sources inside and outside the building. Pollen can travel indoors and disturb the building occupants’ allergies. Other irritants such as fertilizers, lawn chemicals and pesticides can enter into the home during normal day-to-day activities. Items in the building, such as combustion appliances, tobacco byproducts, building materials, household cleaning chemicals, radon, uncontrolled moisture and more, can pose serious health risks. Regardless of the source of the IAQ pollutant, the end result is that they all build up in the building and the pollutants need to be controlled.

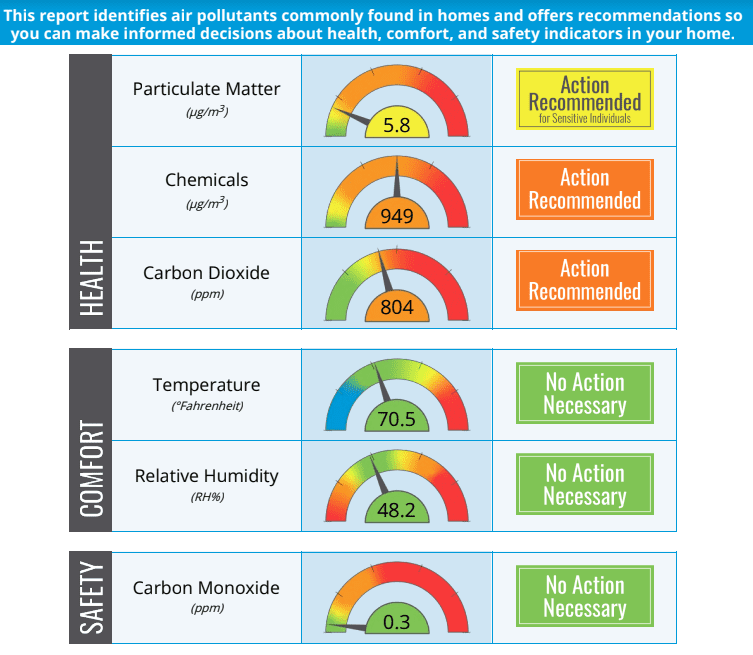

The IAQ level in a building can be measured with a handful of parameters, and the good news is that solutions are available to improve the air quality. There are several IAQ parameters, but for the context of the article, we will focus on the following: particles, chemicals, carbon dioxide, and carbon monoxide, humidity, and temperature. These parameters provide a tremendous overall snapshot of IAQ issues of which every building occupant needs to be aware.

Measuring IAQ Issues

The fundamentals of any successful IAQ program start with testing. Testing is critical to determine “what” type of IAQ issue the customer has and “how” bad it is. Testing should be a standard process of HVAC technicians’ service or maintenance calls. Testing should be as commonplace as using a meter for electrical troubleshooting or refrigerant gauges for taking pressure measurements. The average customer is coping with an IAQ issue and is unaware that it can be measured and resolved. Performing an IAQ test on every call will allow the technician to discover these issues and provide better customer service. It is a significant profit center for contractors as competitors are not likely thinking about indoor air quality.

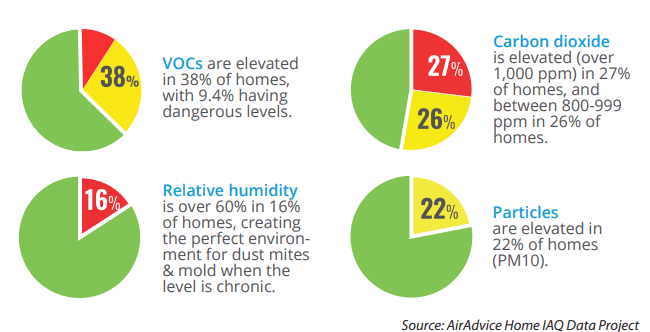

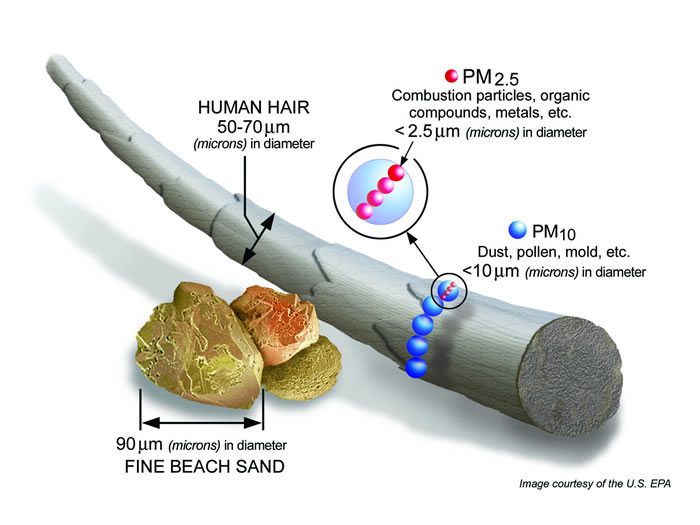

Particles

Particles, also known as “particulate matter,” are a combination of solid and liquid particles that can linger in the air. Particles can come in various shapes and sizes. The concern with particles is that some may be small enough to be inhaled in the lungs and pose a severe health risk as they cannot be filtered easily with our nasal passages and sinuses.

Particle size is measured in micrometers or microns, so the larger the number, the larger the particle. For reference, the sunlight shining through partially open blinds when one can “see” dust particles represents a particle size of about 50 microns. The human eye cannot see particles smaller than 50 microns. The number of particles per volume of air represents particle concentration. Particle concentration is generally measured in µg/m3 or micrograms per cubic meter of air. Smaller particles are the primary concern when it comes to Indoor Air Quality. Unlike dust, soot, and smoke, smaller particles cannot be seen by the naked eye and can cause respiratory issues if inhaled for extended periods.

At 35 µg/m3, The World Health Organization (WHO) reports that our most vulnerable populations, children and the elderly, are more susceptible to respiratory illnesses from exposure to particles in this range. Most concerning is PM2.5, (particulate matter 2.5 microns in diameter.) PM2.5 is considered a fine particle and is listed by the EPA as one of a home’s top five health hazards. PM2.5 particles can even irritate the eyes, and they can enter the bloodstream. Chemical reactions, construction activities, and emission from the combustion process can cause PM2.5.

How to Control Harmful Particles

Remember, particles can come from an array of indoor and outdoor sources. Activities such as cooking, air fresheners, combustion appliances, cigarette smoke, and cleaning products produce particles inside the home. Particles can also come from unsealed ductwork in an unconditioned space, allowing harmful air from attics and crawlspaces to enter the home and cause IAQ complaints. Particles from outside of the home can come from pollen, fertilizers, wildfires, background air pollution, mold spores, dust mites, and animal and insect activity.

Before implementing any solution to control particles, source control is the No. 1 defense against harmful particles. Source control involves stopping the IAQ issues where they are created. For example, combustion appliances like gas ranges and gas ovens that vent directly into the home produce harmful particles while they are being used. Source control for this particular appliance would be installing a range hood to evacuate the harmful particles from the home before they can cause an issue. In this example, using an electric range to eliminate combustion related particles may be a long-term solution. The key here is to stop the particles before they have an opportunity to cause an issue.

Other ways to improve particle concentration include duct cleaning and sealing. Duct cleaning is a process that mechanically removes dirt and debris from the duct system, and duct sealing uses glue or tape to seal any openings in the duct systems.

A professional duct-cleaning job involves using a rated vacuum cleaner with a high-efficiency particle arrestor (HEPA) filter designed for duct cleaning. The duct system’s openings (supply and return registers and grilles) are sealed, and the duct system is placed under negative pressure to capture the particles loosened and removed from the duct the being cleaned. Compressed air and brushes are passed through the system to agitate and loosen the dirt and debris. As the dirt and debris is loosened, it is picked up and carried by the negative pressure created by the HEPA Vac. The HEPA vacuum will collect and trap the dirt and debris.

Duct sealing is another valuable tool to combat the generation of particles. Especially with the return air duct system, harmful particles can enter the HVAC system through the return air. The return air duct system is generally under negative pressure, making it a prime vehicle for IAQ containments to enter the building. These openings include the mechanical fasteners used to connect duct sections together or the seams where the ducts are joined. Not only can duct leaks create poor IAQ, but they also represent a significant energy waste, as conditioned air is not delivered to its intended location. Before sealing ducts, verify that the ducts are properly sized. Duct systems are generally undersized, and sealing an undersized duct will cause equipment performance issues, damage, and improper air distribution.

Other ways to combat harmful particles can be done through filter upgrades and variable speed blower operation. Several filters are on the market and selecting the proper one can be overwhelming. Proper filtration is a vital tool for removing particles in the air stream. Every cubic foot of air inside a building eventually travels through the HVAC system. A high-efficiency filtration system is a great way to capture harmful particles lingering within the home or building. Filters are rated based on their Minimum Efficiency Reporting Value (MERV) rating. The higher the MERV rating, the more efficient the filter removes smaller particles. To capture particles traveling through the HVAC system, a minimum of MERV 13 should be used. Before making any filter replacement or adjustments, verify that the duct system can handle the specified pressure drop of the more efficient filter and verify that the filter will not impact the operation of the HVAC system. For filtration to be most effective, the blower must run frequently. The HVAC technician and the homeowner must work together to balance the cost of operating the blower motor versus the benefits of consistent filtration. With the introduction of electronically commutates motors (ECMs) into the HVAC market, the cost of continuous operation has reduced significantly in recent years, making constant filtration more affordable.

Ventilation is a silver bullet for many IAQ issues, and there are many techniques and methods to implement ventilation to control IAQ. Ventilation is the process of bringing fresher air from outdoors, and this fresher air dilutes the particle levels in the air. To illustrate, think about a sugary drink that is too sweet. The typical reaction would be to add water to dilute the drink to improve its taste. Bringing fresh air from outdoors will dilute the harmful particles and reduce the contaminant levels within the building. Ventilation is essential, and it should be designed by technicians who deeply understand ASHRAE Standard 62.2 “Ventilation for Single-Family Dwellings.” The contractor and the homeowner must work together to design the system to manage the trade-offs between the energy used for ventilation and the benefits of excellent indoor air quality.

Chemicals

Like particles, several government and health organizations consider chemicals to be a concern for indoor air quality. Chemicals mentioned here in this article are described as volatile organic compounds (VOCs). VOCs are carbon-based compounds that can be artificial or naturally occurring. The chemicals from gas or the vapors from the chemicals can be created easily at standard temperatures and pressures. Similar to particles, long-term and high doses or chemical exposure can often lead to respiratory illness and asthma, and they can also trigger allergic reactions. VOC vapors come from chemical compounds like solvents, adhesives, glues, stored fuels, construction materials, carpeting, furniture and standard cleaning chemicals. Formaldehyde and benzene are two very common VOCs in many household items we use.

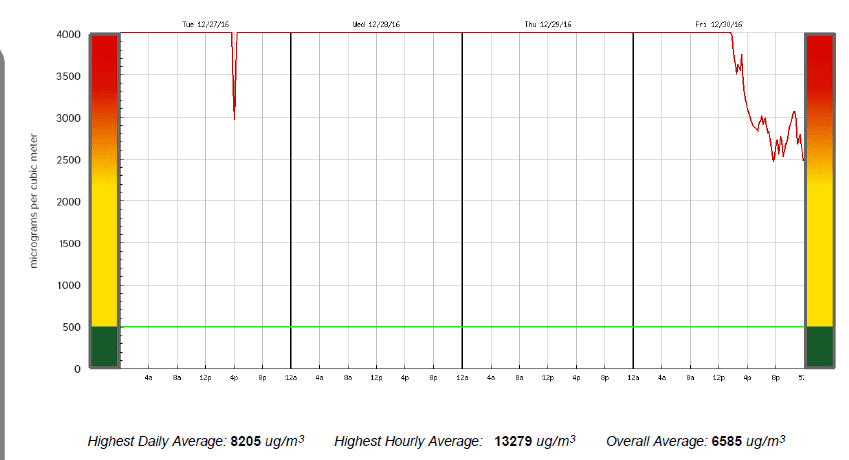

Chemicals are also measured in the air and like particles, chemicals have concentration levels where adverse health reactions will take place. Chemicals are measured based on the containment per unit measurement of air. According to the Air Advice Indoor Air Quality Field Guide, “Chemical pollutants are generally a cause for concern when average levels are above 500 micrograms per cubic meter of air.” At this level or above, chemical exposure may cause the following: pink eye, nose and throat irritation, headache, allergic reaction to the skin, shortness of breath, liver problems, nausea, vomiting, bloody nose, fatigue, and dizziness.

How to Control Chemical Exposure

Source control is still the best defense against any IAQ issue, including chemicals. The EPA has several behaviors or actions the building occupants can take to reduce the likelihood of illness due to chemical exposure. Remember that many daily household products have high amounts of chemicals, so follow the labels and instructions carefully. Another excellent practical behavior is to properly discard any partially full containers of old or unneeded chemicals. Other practical advice from the EPA on using chemicals includes buying limited qualities and avoiding mixing chemicals not specially designed to be mixed. Lastly, avoid storing chemicals without caps or containers.

After source control measures are taken, the harmful chemicals must be captured, destroyed, or diluted through ventilation. Chemicals in the air can be captured using a filtering media with activated charcoal or carbon. Activated charcoal or carbon traps the chemicals using a chemical force or absorption force, which removes the chemicals from the air stream. For the capturing technique to work effectively, the blower on the HVAC system must be operating so the chemical can be removed from the air stream.

Chemicals in the can be destroyed using a photo catalytic oxidizer or (PCO) device. A PCO device is installed in the HVAC system ductwork. As airflow is circulated throughout the duct system, the PCO will work to destroy the chemicals until they are broken down into harmless elements, CO2 and water vapor. The PCO device uses a UV light and a catalytic Oxidizer to accomplish this reaction.

Ventilation is another great solution to “handle” chemicals inside the buildings. Like the particles above, ventilation plays the same role with particles as it does with chemicals.

References

- Air Advice. Indoor Air Quality Field Guide. Air Advice 2021, 2021.

- Building Performance Institute. Health Housing Principles. 1 ed., Saratoga Springs, Building Performance Institute, 2020.

- BCC Research. (2023). U.S. Indoor Air Quality Market. BCC Research. https://www.bccresearch.com/market-research/environment/us-indoor-air-quality-market.html

Stay tuned for Part 2 of this article, which will discuss IAQ issues related to CO2, CO, temperature, and humidity.